Page 1093 - YG 2019

P. 1093

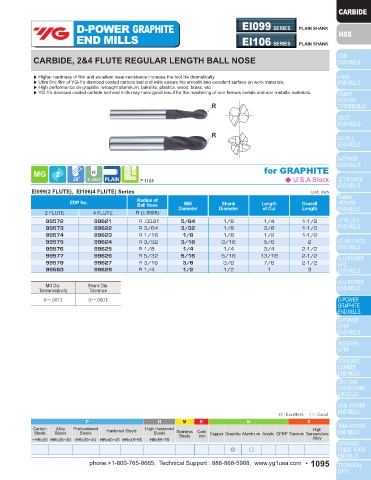

D-POWER GRAPHITE D-POWER GRAPHITE EI099 SERIES PLAIN SHANK

END MILLS EI107 SERIES PLAIN SHANK END MILLS EI106 SERIES PLAIN SHANK

CARBIDE, 4(2) FLUTE REGULAR LENGTH CARBIDE, 2&4 FLUTE REGULAR LENGTH BALL NOSE

▶ Higher hardness of film and excellent wear-resistance increase the tool life dramatically. ▶ Higher hardness of film and excellent wear-resistance increase the tool life dramatically.

▶ Ultra fine film of YG-1’s diamond coated carbide end mills ensure the smooth and excellent surface on work materials. ▶ Ultra fine film of YG-1’s diamond coated carbide ball end mills ensure the smooth and excellent surface on work materials.

▶ High performance on graphite, wrought aluminum, bakelite, plastics, wood, brass, etc. ▶ High performance on graphite, wrought aluminum, bakelite, plastics, wood, brass, etc.

▶ YG-1’s diamond coated carbide end mills may have good result for the machining of non-ferrous metals and non-metallic materials. ▶ YG-1’s diamond coated carbide ball end mills may have good result for the machining of non-ferrous metals and non-metallic materials.

R

↙

R

↙

for GRAPHITE for GRAPHITE

P.1105 ◆ U.S.A Stock P.1104 ◆ U.S.A Stock

Unit : Inch EI099(2 FLUTE), EI106(4 FLUTE) Series Unit : Inch

Shank

Mill

EDP No. Diameter Diameter Length Overall EDP No. Radius of Mill Shank Length Overall

Length

of Cut

Ball Nose

★ 99686 1/64 1/8 3/65 1-1/2 2 FLUTE 4 FLUTE R (±.0008) Diameter Diameter of Cut Length

99629 1/8 1/8 1/2 1-1/2 99572 99621 R .0391 5/64 1/8 1/4 1-1/2

99630 3/16 3/16 5/8 2 99573 99622 R 3/64 3/32 1/8 3/8 1-1/2

99631 1/4 1/4 3/4 2-1/2 99574 99623 R 1/16 1/8 1/8 1/2 1-1/2

99632 5/16 5/16 13/16 2-1/2 99575 99624 R 3/32 3/16 3/16 5/8 2

99633 3/8 3/8 7/8 2-1/2 99576 99625 R 1/8 1/4 1/4 3/4 2-1/2

99635 1/2 1/2 1 3 99577 99626 R 5/32 5/16 5/16 13/16 2-1/2

★ 2Flute ▶Recommended Cutting Condition 99578 99627 R 3/16 3/8 3/8 7/8 2-1/2

▶Cutting speed : 500~1200 SFPM 99583 99628 R 1/4 1/2 1/2 1 3

▶ Feed : .002~.006 inch/tooth

Mill Dia. Shank Dia.

Tolerance(inch) Tolerance Mill Dia. Shank Dia.

Tolerance(inch) Tolerance

0~-.0012 0~-.0003

0~-.0012 0~-.0003

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened Hardened Steels High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Steels

Iron

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Steels Iron Alloy

◎ ○ ◎ ○

1094 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 1095