Page 1153 - YG 2019

P. 1153

CARBIDE CARBIDE

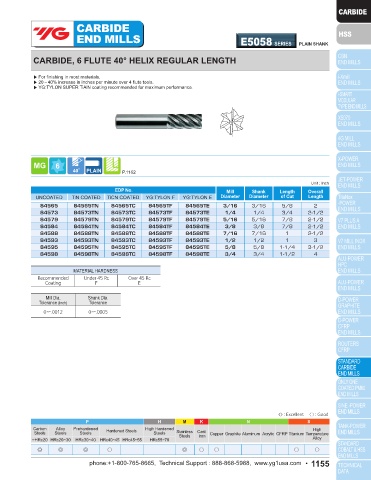

END MILLS E5073 SERIES PLAIN SHANK END MILLS E5058 SERIES PLAIN SHANK

CARBIDE, 5 FLUTE 45° HELIX EXTRA LONG LENGTH CARBIDE, 6 FLUTE 40° HELIX REGULAR LENGTH

▶ Designed to machine stainless steel, inconels and other alloys. ▶ For finishing in most materials.

▶ The new design of stub length allows cutting at maximum speeds and feeds with minimum deflection ▶ 20〜40% increase in inches per minute over 4 flute tools.

▶ 5 Flute and 45° medium helix allow harmonic balance and smooth cutting. ▶ YG:TYLON SUPER TiAlN coating recommended for maximum performance.

P.1162 P.1162

Unit : Inch Unit : Inch

EDP No. Mill Shank Length Overall EDP No. Mill Shank Length Overall

UNCOATED TiN COATED TiCN COATED YG:TYLON F YG:TYLON E Diameter Diameter of Cut Length UNCOATED TiN COATED TiCN COATED YG:TYLON F YG:TYLON E Diameter Diameter of Cut Length

59579 59579TN 59579TC 59579TF 59579TE 5/16 5/16 2-1/8 4 84565 84565TN 84565TC 84565TF 84565TE 3/16 3/16 5/8 2

59584 59584TN 59584TC 59584TF 59584TE 3/8 3/8 2-1/2 6 84573 84573TN 84573TC 84573TF 84573TE 1/4 1/4 3/4 2-1/2

59593 59593TN 59593TC 59593TF 59593TE 1/2 1/2 3-1/8 6 84579 84579TN 84579TC 84579TF 84579TE 5/16 5/16 7/8 2-1/2

59595 59595TN 59595TC 59595TF 59595TE 5/8 5/8 4 6 84584 84584TN 84584TC 84584TF 84584TE 3/8 3/8 7/8 2-1/2

59598 59598TN 59598TC 59598TF 59598TE 3/4 3/4 4 6 84588 84588TN 84588TC 84588TF 84588TE 7/16 7/16 1 2-1/2

59600 59600TN 59600TC 59600TF 59600TE 1 1 4-1/8 7 84593 84593TN 84593TC 84593TF 84593TE 1/2 1/2 1 3

84595 84595TN 84595TC 84595TF 84595TE 5/8 5/8 1-1/4 3-1/2

Mill Dia. Shank Dia. 84598 84598TN 84598TC 84598TF 84598TE 3/4 3/4 1-1/2 4

Tolerance (inch) Tolerance

0~-.0012 0~-.0003 MATERIAL HARDNESS

Recommended Under 45 Rc Over 45 Rc

Coating F E

Mill Dia. Shank Dia.

Tolerance (inch) Tolerance

0~-.0012 0~-.0005

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened Hardened Steels High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Steels

Iron

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Steels Iron Alloy

◎ ◎ ◎ ○ ◎ ○ ○ ○ ○ ◎ ◎ ◎ ○ ◎ ○ ○ ○ ○

1154 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 1155