Page 1154 - YG 2019

P. 1154

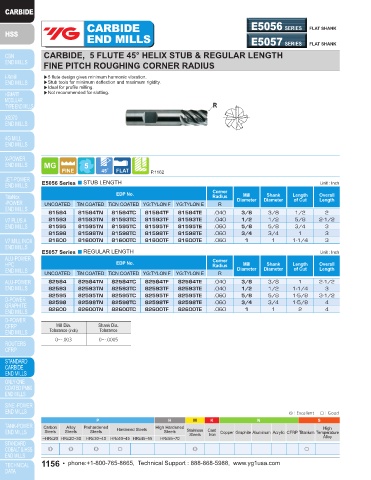

CARBIDE E5056 SERIES FLAT SHANK CARBIDE

END MILLS E5057 SERIES FLAT SHANK END MILLS E5077 SERIES PLAIN SHANK

CARBIDE, 5 FLUTE 45° HELIX STUB & REGULAR LENGTH CARBIDE, 3 FLUTE TAPER

FINE PITCH ROUGHING CORNER RADIUS

▶5 flute design gives minimum harmonic vibration. ▶Designed for milling die cavity.

▶Stub tools for minimum deflection and maximum rigidity. ▶Many different center line angles are available on your job requirement.

▶Ideal for profile milling.

▶Not recommended for slotting.

R

↙

P.1162 P.1162

E5056 Series ■ STUB LENGTH Unit : Inch Unit : Inch

EDP No. Corner Mill Shank Length Overall EDP No. Cutting Shank Length Overall Center

Radius

Ling

Small

UNCOATED TiN COATED TiCN COATED YG:TYLON F YG:TYLON E R Diameter Diameter of Cut Length UNCOATED TiN COATED TiCN COATED YG:TYLON F YG:TYLON E Diameter Diameter of Cut Length Angle

81584 81584TN 81584TC 81584TF 81584TE .040 3/8 3/8 1/2 2 87552 87552TN 87552TC 87552TF 87552TE 1/8 1/4 1-1/2 3 1°

81593 81593TN 81593TC 81593TF 81593TE .040 1/2 1/2 5/8 2-1/2 87553 87553TN 87553TC 87553TF 87553TE 1/8 1/4 1-1/2 3 1.5°

81595 81595TN 81595TC 81595TF 81595TE .060 5/8 5/8 3/4 3 87554 87554TN 87554TC 87554TF 87554TE 1/8 1/4 1-1/4 3 2°

81598 81598TN 81598TC 81598TF 81598TE .060 3/4 3/4 1 3 87556 87556TN 87556TC 87556TF 87556TE 1/8 1/4 1 3 3°

81600 81600TN 81600TC 81600TF 81600TE .060 1 1 1-1/4 3 87560 87560TN 87560TC 87560TF 87560TE 1/8 1/4 3/4 3 5°

87564 87564TN 87564TC 87564TF 87564TE 1/8 1/4 1/2 3 7°

E5057 Series ■ REGULAR LENGTH Unit : Inch 87570 87570TN 87570TC 87570TF 87570TE 3/32 1/4 1/2 3 10°

EDP No. Corner Mill Shank Length Overall 87572 87572TN 87572TC 87572TF 87572TE 3/16 3/8 1-3/4 3-1/2 1°

Radius

UNCOATED TiN COATED TiCN COATED YG:TYLON F YG:TYLON E R Diameter Diameter of Cut Length 87573 87573TN 87573TC 87573TF 87573TE 3/16 3/8 1-3/4 3-1/2 1.5°

87574TE

3/16

87574

87574TC

87574TN

87574TF

3-1/2

3/8

1-3/4

2°

82584 82584TN 82584TC 82584TF 82584TE .040 3/8 3/8 1 2-1/2 87576 87576TN 87576TC 87576TF 87576TE 5/32 3/8 1-3/4 3-1/2 3°

82593 82593TN 82593TC 82593TF 82593TE .040 1/2 1/2 1-1/4 3 87580 87580TN 87580TC 87580TF 87580TE 1/8 3/8 1-1/2 3-1/2 5°

82595 82595TN 82595TC 82595TF 82595TE .060 5/8 5/8 1-5/8 3-1/2 87584 87584TN 87584TC 87584TF 87584TE 1/8 3/8 1 3-1/2 7°

82598 82598TN 82598TC 82598TF 82598TE .060 3/4 3/4 1-5/8 4 87590 87590TN 87590TC 87590TF 87590TE 1/8 3/8 3/4 3-1/2 10°

82600 82600TN 82600TC 82600TF 82600TE .060 1 1 2 4 87592 87592TN 87592TC 87592TF 87592TE 1/4 1/2 2 4 1°

87594 87594TN 87594TC 87594TF 87594TE 1/4 1/2 2 4 2°

Mill Dia. Shank Dia. 87596 87596TN 87596TC 87596TF 87596TE 1/4 1/2 2 4 3°

Tolerance (inch) Tolerance 87600 87600TN 87600TC 87600TF 87600TE 1/4 1/2 1-1/4 4 5°

87902 87902TN 87902TC 87902TF 87902TE 3/16 1/2 1-1/4 4 7°

0~-.003 0~-.0005

87903 87903TN 87903TC 87903TF 87903TE 1/8 1/2 1 4 10°

Cutting Small Dia. Shank Dia. Center Line Angle

Tolerance(mm) Tolerance Tolerance

Ø1/16 ~ Ø1/4 0~-.0020 0~-.0005 ±5´

Ø17/64 ~ Ø1 0~-.0030

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened Hardened Steels High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Steels

Iron

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Steels Iron Alloy

◎ ◎ ◎ ○ ◎ ○ ◎ ◎ ◎ ○ ○ ○ ○ ○

1156 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 1157