Page 1425 - YG 2019

P. 1425

ROTARY

TOOL HOLDERS

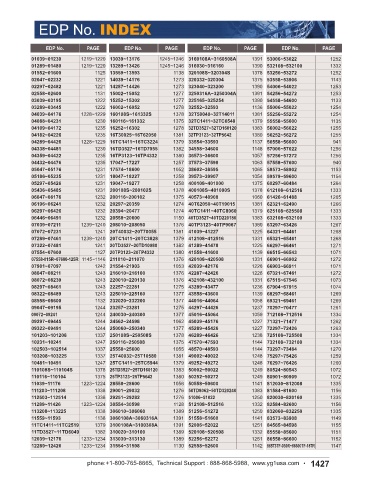

EDP No. PAGE EDP No. PAGE EDP No. PAGE EDP No. PAGE

TECHNICAL INFORMATION (T.I.R and TOLEARANCE) 01039~01230 1219~1220 13039~13176 1245~1246 3160108A~3160508A 1391 53006~53022 1252

01289~01480 1219~1220 13289~13426 1245~1246 316030~316160 1390 532108~532100 1332

01552~01600 1125 13559~13593 1138 320108S~320304S 1378 53256~53272 1252

02047~02232 1221 14039~14176 1273 320332~320304 1375 53558~53906 1143

T.I.R (Total Indicated Run-out) 02297~02482 1221 14287~14426 1273 323040~323200 1390 54006~54022 1253

02558~02600 1131 15002~15052 1277 3250316A~3250304A 1391 54256~54272 1253

03039~03195 1222 15252~15302 1277 325165~325254 1390 54558~54600 1133

HYDRAULIC CHUCK 03289~03445 1222 16002~16052 1278 32552~32593 1136 55006~55022 1254

Concentric to 0.00012” T.I.R (at 3D) 04039~04176 1228~1229 160108S~161332S 1378 32T50040~32T14011 1381 55256~55272 1254

04088~04231 1230 160116~161332 1375 32TC1411~32TC6548 1379 55558~55600 1135

SHRINK FIT HOLDER 04109~04172 1235 16252~16302 1278 32TD3527~32TD160120 1383 56002~56022 1255

1235 16T30025~16T62050

Concentric to 0.00012” T.I.R (at I.D) 04182~04226 1228~1229 16TC1411~16TC3224 1381 32TP3123~32TP5642 1380 56252~56272 1255

04289~04426

1379 33554~33593

941

1137 56558~56600

04338~04481 1230 16TD3527~16TD7055 1382 34558~34600 1148 57006~57022 1256

ER COLLET CHUCK 04359~04422 1235 16TP3123~16TP4332 1380 36573~36600 1057 57256~57272 1256

Concentric to 0.0002” T.I.R (at I.D) 04432~04476 1235 17047~17227 1257 37573~37598 1063 57558~57600 940

05047~05176 1231 17574~18600 1052 38602~38595 1065 58573~58902 1153

END MILL HOLDER 05186~05235 1231 18047~18227 1258 39573~39907 1054 59579~59600 1154

Concentric to 0.0002” T.I.R (at I.D) 05297~05426 1231 19047~19277 1258 400108~401000 1375 60297~60484 1264

05436~05485

1378 400108S~401000S

1378 612108~612516

1231 200108S~200102S

1333

06047~06176 1232 200116~200102 1375 40573~40908 1060 61426~61488 1265

SLITTING SAW ARBOR 06196~06241 1232 20297~20359 1274 40T62050~40T19015 1381 62321~62490 1266

Face perpendicular to taper within 0.0002” T.I.R (at I.D) 06297~06426 1232 20394~20477 1274 40TC1411~40TC8060 1379 625108~625508 1333

06446~06491 1232 20558~20600 1150 40TD3527~40TD220180 1383 632108~632100 1333

STUB ARBOR 07039~07211 1239~1240 208010~208050 1376 40TP3123~40TP9067 1380 63297~63426 1267

1241 20T40032~20T70055

Face perpendicular to taper within 0.0002” T.I.R (at I.D) 07072~07231 1239~1240 20TC1411~20TC3828 1381 41039~41227 1225 64321~64461 1268

1379 412108~412516

1331 65321~65461

1268

07289~07461

SHELL MILL ARBOR 07322~07481 1241 20TD3527~20TD10080 1382 41289~41478 1225 66297~66461 1271

1380 41558~41600

1071

1127 20TP3123~20TP4332

07554~07600

1139 66515~66543

Face perpendicular to taper within 0.0001” T.I.R 07558-015R~07600-125R 1145~1146 211010~211070 1376 420108~420508 1331 66901~66902 1272

Out diameter to taper within 0.0002” T.I.R 07901~07097 1242 21554~21903 1053 42039~42176 1226 66903~66911 1071

08047~08211 1243 216010~216100 1376 42287~42426 1226 67321~67461 1272

MORSE & JACOBS TAPER ARBOR 08072~08239 1243 220010~220130 1376 432108~432100 1331 67515~67546 1073

1243 22257~22281

08297~08461

1275 43289~43477

1074

1236 67904~67915

Concentric to 0.0003” T.I.R 08322~08489 1243 225010~225160 1377 43558~43600 1139 68297~68461 1269

08558~08600 1132 232020~232200 1377 44016~44064 1058 69321~69461 1269

* To put tool precisely on spindle center line for getting correct T.I.R. 09047~09195 1244 23257~23281 1275 44297~44426 1237 70297~70477 1261

09072~09241 1244 240030~240300 1377 45016~45064 1059 712108~712516 1334

09297~09445 1244 24562~24598 1062 45039~45176 1227 71321~71477 1262

09322~09491 1244 250060~250340 1377 45289~45426 1227 72297~72426 1263

TAPER AT3 101203~101208 1337 250108S~250508S 1378 46289~46426 1238 725108~725508 1334

AT3 or better accuracy on all shank tapers #30 0.000078” 10231~10241 1247 250116~250508 1375 47570~47593 1144 732108~732100 1334

#40 0.00012” 102503~102514 1337 25558~25600 1055 48570~48593 1144 73297~73484 1270

1248 75297~75426

1259

1381 49002~49022

103208~103225

1337 25T40032~25T10580

Accurate and rigid tool holder mounting to spindle #50 0.00016” 10481~10491 1247 25TC1411~25TC5944 1379 49252~49272 1248 76297~76426 1260

110108S~110104S 1378 25TD3527~25TD160120 1383 50002~50022 1249 80524~80543 1072

110116~110104 1375 25TP3123~25TP5642 1380 50252~50272 1249 80901~80909 1072

The bore diameter of all tool holders is controlled by H5 grade tolerance limit. 11039~11176 1223~1224 28558~28600 1056 50558~50600 1141 812030~812008 1335

111203~111208 1338 29001~29032 1276 50TD8062~50TD320240 1383 81584~81600 1156

112503~112514 1338 29251~29282 1276 51006~51022 1250 820030~820160 1335

11289~11426 1223~1224 30554~30598 1128 512108~512516 1332 82584~82600 1156

113208~113225 1338 306010~306060 1389 51256~51272 1250 832060~832250 1335

11559~11593 1138 3060108A~3060316A 1391 51558~51600 1141 83573~83908 1149

11TC1411~11TC2519 1379 3100108A~3100308A 1391 52006~52022 1251 84565~84598 1155

11TD3527~11TD6049 1382 310020~310100 1389 520108~520508 1332 85558~85600 1151

12039~12176 1233~1234 313030~313130 1389 52256~52272 1251 86558~86600 1152

12289~12426 1233~1234 31554~31598 1130 52558~52600 1142 86573TF-030R~86600TF-187R 1147

1426 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 1427