Page 16 - YG 2019

P. 16

◆

◆

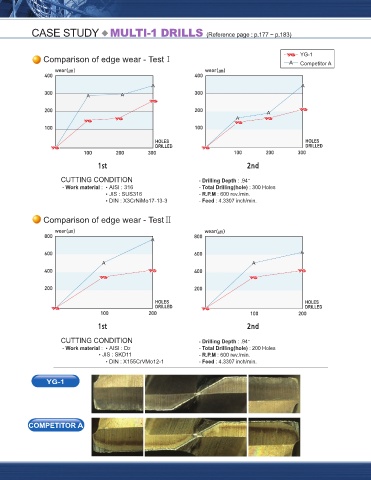

CASE STUDY MULTI-1 DRILLS (Reference page : p.177 ~ p.183) CASE STUDY COMBO TAPS (Reference page : p.363 ~ p.388)

YG-1

Comparison of edge wear - TestⅠ

Competitor A

COMBO - SPIRAL FLUTE YG-1(Total Tapping 204 Holes)

Surface Roughness of Work Piece

Cutting Condition

- Tools : Combo Spiral Flute Tap

- Size : M8×1.25

- Work Material : •AISI : 1045 204 Holes ▶

•JIS : S45C(HRc35) COMPETITOR A (Total Tapping 159 Holes)

•DIN : C45 Surface Roughness of Work Piece

HOLES HOLES - Tapping Depth: .79˝

DRILLED DRILLED - Coolant : Water Soluble Oil

- SFM (Tapping Speed) : 33 ft/min.

1st 2nd

159 Holes ▶

CUTTING CONDITION - Drilling Depth : .94˝ COMPETITOR B (Total Tapping 204 Holes)

- Work material : •AISI : 316 - Total Drilling(hole) : 300 Holes

•JIS : SUS316 - R.P.M : 600 rev./min. Surface Roughness of Work Piece

•DIN : X3CrNiMo17-13-3 - Feed : 4.3307 inch/min.

Comparison of edge wear - TestⅡ

204 Holes ▶

COMBO - SPIRAL POINT YG-1(Total Tapping 450 Holes)

HOLES HOLES

DRILLED DRILLED Cutting Condition

- Tools : Combo Spiral Point Tap

1st 2nd - Size : M2×0.4 Thread Flute

- Work Material : •AISI : 1045

CUTTING CONDITION - Drilling Depth : .94˝ •JIS : S45C(HRc35) COMPETITOR A (Total Tapping 318 Holes)

- Work material : •AISI : D2 - Total Drilling(hole) : 200 Holes •DIN : C45

•JIS : SKD11 - R.P.M : 600 rev./min. - Tapping Depth : .24˝

•DIN : X155CrVMo12-1 - Feed : 4.3307 inch/min. - Coolant : Tapping Oil

- SFM (Tapping Speed) : 33 ft/min. Tool was broken after tapping 318 holes

YG-1

COMPETITOR B (Total Tapping 103 Holes)

COMPETITOR A Tool was broken after tapping 103 holes