Page 11 - YG 2019

P. 11

(Reference page :

◆

◆

CASE STUDY DREAM DRILLS-HIGH FEED (Reference page : p.91 ~ p.102) CASE STUDY DREAM DRILLS-FLAT BOTTOM p.103 ~ p.110)

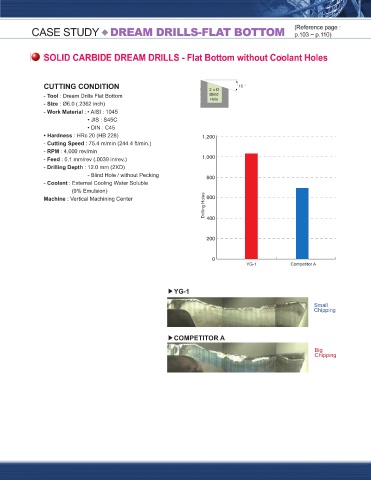

FEATURES OF DREAM DRILLS-HIGH FEED SOLID CARBIDE DREAM DRILLS - Flat Bottom without Coolant Holes

Dream Drills-High Feed offers 1.5 to 2 times higher feeding speed compared to

conventional 2-flute drills. The unique flute design and exceptional surface finish promises CUTTING CONDITION 2 x D 15 °

extraordinary chip evacuation. - Tool : Dream Drills Flat Bottom Blind

Hole

- Size : Ø6.0 (.2362 inch)

- Work Material : • AISI : 1045

• JIS : S45C

• DIN : C45

YG-1 (Total Drilling 330 Holes) Cutting Condition • Hardness : HRc 20 (HB 228) 1,200

Tools : DGR495100 - Cutting Speed : 75.4 m/min (244.4 ft/min.)

(Dream Drills High Feed) - RPM : 4,000 rev/min

Size : Ø10 x 10 x 61 x 103 - Feed : 0.1 mm/rev (.0039 in/rev.) 1,000

Work Material : • AISI : 1045 - Drilling Depth : 12.0 mm (2XD)

• JIS : S45C (HRc20) - Blind Hole / without Pecking 800

• DIN : C45 - Coolant : External Cooling Water Soluble

R.P.M : 3,200 rev./min. (9% Emulsion)

COMPETITOR A (Total Drilling 330 Holes) Feed : .0197 inch/rev. Machine : Vertical Machining Center Drilling Holes 600

Drilling Depth : 1.97˝ (5xD)

Drilling Method : Blind Hole

Coolant : Wet Cut 400

Machine : Machining Center

200

0

YG-1 Competitor A

COMPETITOR B (Total Drilling 330 Holes)

▶YG-1

Small

Chipping

▶COMPETITOR A

Big

Chipping

Productivity (Carbon Steel)

1.6 times UP

Ø 10 5xD viy t

Productivity 39.5 inch/min. 62.7 inch/min.

Pr oduct i