Page 191 - YG 2019

P. 191

HPD DRILLS HPD DRILLS

DJ544 SERIES DJ544 SERIES

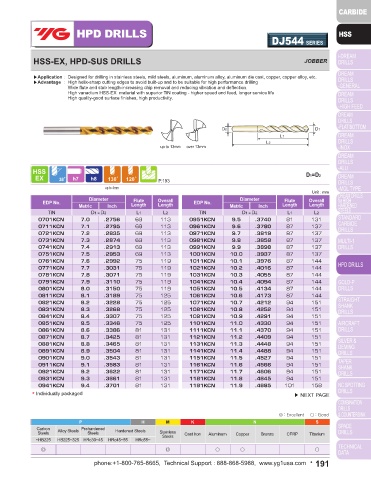

HSS-EX, HPD-SUS DRILLS JOBBER HSS-EX, HPD-SUS DRILLS JOBBER

▶Application : Designed for drilling in stainless steels, mild steels, aluminum, aluminum alloy, aluminum die cast, copper, copper alloy, etc. ▶Application : Designed for drilling in stainless steels, mild steels, aluminum, aluminum alloy, aluminum die cast, copper, copper alloy, etc.

▶Advantage : High helix-sharp cutting edges to avoid built-up and to be suitable for high performance drilling ▶Advantage : High helix-sharp cutting edges to avoid built-up and to be suitable for high performance drilling

Wide flute and stub length-increasing chip removal and reducing vibration and deflection. Wide flute and stub length-increasing chip removal and reducing vibration and deflection.

High vanadium HSS-EX material with superior TiN coating - higher speed and feed, longer service life High vanadium HSS-EX material with superior TiN coating - higher speed and feed, longer service life

High quality-good surface finishes, high productivity. High quality-good surface finishes, high productivity.

D2 D1 D2 D1

L1 L1

L2 L2

up to 13mm over 13mm up to 13mm over 13mm

D1=D2 D1=D2

130 120 P.193 130 120 P.193

up to 4mm over 4mm up to 4mm

Unit : mm Unit : mm

Diameter Flute Overall Diameter Flute Overall Diameter Flute Overall Diameter Flute Overall

EDP No. EDP No. EDP No. EDP No.

Metric Inch Length Length Metric Inch Length Length Metric Inch Length Length Metric Inch Length Length

TiN D1 = D2 L1 L2 TiN D1 = D2 L1 L2 TiN D1 = D2 L1 L2 TiN D1 = D2 L1 L2

0201KCN 2.0 .0787 24 56 0451KCN 4.5 .1772 47 91 0701KCN 7.0 .2756 69 113 0951KCN 9.5 .3740 81 131

0211KCN 2.1 .0827 24 56 0461KCN 4.6 .1811 47 91 0711KCN 7.1 .2795 69 113 0961KCN 9.6 .3780 87 137

0221KCN 2.2 .0866 27 59 0471KCN 4.7 .1850 47 91 0721KCN 7.2 .2835 69 113 0971KCN 9.7 .3819 87 137

0231KCN 2.3 .0906 27 59 0481KCN 4.8 .1890 52 96 0731KCN 7.3 .2874 69 113 0981KCN 9.8 .3858 87 137

0241KCN 2.4 .0945 30 62 0491KCN 4.9 .1929 52 96 0741KCN 7.4 .2913 69 113 0991KCN 9.9 .3898 87 137

0251KCN 2.5 .0984 30 62 0501KCN 5.0 .1969 52 96 0751KCN 7.5 .2953 69 113 1001KCN 10.0 .3937 87 137

0261KCN 2.6 .1024 30 62 0511KCN 5.1 .2008 52 96 0761KCN 7.6 .2992 75 119 1011KCN 10.1 .3976 87 144

0271KCN 2.7 .1063 33 65 0521KCN 5.2 .2047 52 96 0771KCN 7.7 .3031 75 119 1021KCN 10.2 .4016 87 144

0281KCN 2.8 .1102 33 65 0531KCN 5.3 .2087 52 96 0781KCN 7.8 .3071 75 119 1031KCN 10.3 .4055 87 144

0291KCN 2.9 .1142 33 65 0541KCN 5.4 .2126 57 101 0791KCN 7.9 .3110 75 119 1041KCN 10.4 .4094 87 144

0301KCN 3.0 .1181 33 65 0551KCN 5.5 .2165 57 101 0801KCN 8.0 .3150 75 119 1051KCN 10.5 .4134 87 144

0311KCN 3.1 .1220 36 68 0561KCN 5.6 .2205 57 101 0811KCN 8.1 .3189 75 125 1061KCN 10.6 .4173 87 144

0321KCN 3.2 .1260 36 68 0571KCN 5.7 .2244 57 101 0821KCN 8.2 .3228 75 125 1071KCN 10.7 .4212 94 151

0331KCN 3.3 .1299 36 68 0581KCN 5.8 .2283 57 101 0831KCN 8.3 .3268 75 125 1081KCN 10.8 .4252 94 151

0341KCN 3.4 .1339 39 71 0591KCN 5.9 .2323 57 101 0841KCN 8.4 .3307 75 125 1091KCN 10.9 .4291 94 151

0351KCN 3.5 .1378 39 71 0601KCN 6.0 .2362 57 101 0851KCN 8.5 .3346 75 125 1101KCN 11.0 .4330 94 151

0361KCN 3.6 .1417 39 71 0611KCN 6.1 .2402 63 107 0861KCN 8.6 .3386 81 131 1111KCN 11.1 .4370 94 151

0371KCN 3.7 .1457 39 71 0621KCN 6.2 .2441 63 107 0871KCN 8.7 .3425 81 131 1121KCN 11.2 .4409 94 151

0381KCN 3.8 .1496 43 75 0631KCN 6.3 .2480 63 107 0881KCN 8.8 .3465 81 131 1131KCN 11.3 .4448 94 151

0391KCN 3.9 .1535 43 75 0641KCN 6.4 .2520 63 107 0891KCN 8.9 .3504 81 131 1141KCN 11.4 .4488 94 151

0401KCN 4.0 .1575 43 75 0651KCN 6.5 .2559 63 107 0901KCN 9.0 .3543 81 131 1151KCN 11.5 .4527 94 151

0411KCN 4.1 .1614 43 87 0661KCN 6.6 .2598 63 107 0911KCN 9.1 .3583 81 131 1161KCN 11.6 .4566 94 151

0421KCN 4.2 .1654 43 87 0671KCN 6.7 .2638 63 107 0921KCN 9.2 .3622 81 131 1171KCN 11.7 .4606 94 151

0431KCN 4.3 .1693 47 91 0681KCN 6.8 .2677 69 113 0931KCN 9.3 .3661 81 131 1181KCN 11.8 .4645 94 151

0441KCN 4.4 .1732 47 91 0691KCN 6.9 .2717 69 113 0941KCN 9.4 .3701 81 131 1191KCN 11.9 .4685 101 158

* Individually packaged ▶ NEXT PAGE * Individually packaged ▶ NEXT PAGE

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Prehardened Carbon Prehardened

Steels Alloy Steels Steels Hardened Steels Stainless Cast Iron Aluminum Copper Bronze CFRP Titanium Steels Alloy Steels Steels Hardened Steels Stainless Cast Iron Aluminum Copper Bronze CFRP Titanium

Steels

Steels

~HB225 HB225~325 HRc30~45 HRc45~55 HRc55~ ~HB225 HB225~325 HRc30~45 HRc45~55 HRc55~

◎ ◎ ○ ○ ○ ◎ ◎ ○ ○ ○

190 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 191