Page 193 - YG 2019

P. 193

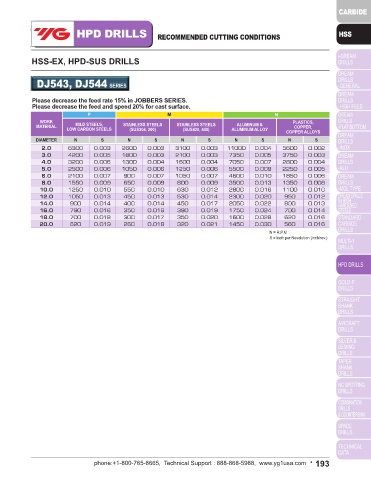

HPD DRILLS HPD DRILLS RECOMMENDED CUTTING CONDITIONS

DJ544 SERIES

HSS-EX, HPD-SUS DRILLS JOBBER HSS-EX, HPD-SUS DRILLS

▶Application : Designed for drilling in stainless steels, mild steels, aluminum, aluminum alloy, aluminum die cast, copper, copper alloy, etc.

▶Advantage : High helix-sharp cutting edges to avoid built-up and to be suitable for high performance drilling

Wide flute and stub length-increasing chip removal and reducing vibration and deflection. DJ543, DJ544 SERIES

High vanadium HSS-EX material with superior TiN coating - higher speed and feed, longer service life

High quality-good surface finishes, high productivity. Please decrease the feed rate 15% in JOBBERS SERIES.

Please decrease the feed and speed 20% for cast surface.

P M N

WORK PLASTICS,

MATERIAL MILD STEELS, STAINLESS STEELS STAINLESS STEELS ALUMINUM & COPPER,

D2 D1 LOW CARBON STEELS (SUS304, 200) (SUS420, 440) ALUMINUM ALLOY

COPPER ALLOYS

L1

DIAMETER N S N S N S N S N S

L2

up to 13mm over 13mm 2.0 6300 0.003 2600 0.003 3100 0.003 11000 0.004 5600 0.002

3.0 4200 0.005 1800 0.003 2100 0.003 7350 0.005 3750 0.003

4.0 3200 0.006 1300 0.004 1600 0.004 7050 0.007 2800 0.004

5.0 2500 0.006 1050 0.006 1250 0.006 5500 0.009 2250 0.005

D1=D2 6.0 2100 0.007 900 0.007 1050 0.007 4600 0.010 1850 0.006

130 120 P.193 8.0 1550 0.009 650 0.009 800 0.009 3500 0.013 1350 0.008

up to 4mm over 4mm 10.0 1250 0.010 550 0.010 630 0.012 2800 0.016 1100 0.010

Unit : mm

Diameter Flute Overall Diameter Flute Overall 12.0 1050 0.013 450 0.013 530 0.014 2300 0.020 950 0.012

EDP No. EDP No. 14.0 900 0.014 400 0.014 450 0.017 2050 0.022 800 0.013

Metric Inch Length Length Metric Inch Length Length

TiN D1 = D2 L1 L2 TiN D1 = D2 L1 L2 16.0 790 0.016 350 0.016 390 0.019 1750 0.024 700 0.014

1201KCN 12.0 .4724 101 158 1501KCN 15.0 .5905 109 169 18.0 700 0.018 300 0.017 350 0.020 1600 0.028 620 0.016

1211KCN 12.1 .4764 101 158 1551KCN 15.5 .6102 112 172 20.0 620 0.019 260 0.018 320 0.021 1450 0.030 560 0.016

1221KCN 12.2 .4803 101 158 1561KCN 15.6 .6141 112 172 N = R.P.M

1231KCN 12.3 .4843 101 158 1601KCN 16.0 .6299 112 172 S = Inch per Revolution (inch/rev.)

1241KCN 12.4 .4882 101 158 1651KCN 16.5 .6495 115 181

1251KCN 12.5 .4921 101 158 1701KCN 17.0 .6692 115 181

1261KCN 12.6 .4961 101 158 1751KCN 17.5 .6889 118 184

1271KCN 12.7 .5000 101 158 1761KCN 17.6 .6929 118 184

1281KCN 12.8 .5039 101 158 1801KCN 18.0 .7087 118 184

1291KCN 12.9 .5079 101 158 1851KCN 18.5 .7283 122 188

1301KCN 13.0 .5118 101 158 1901KCN 19.0 .7480 122 188

1351KCN 13.5 .5314 106 166 1951KCN 19.5 .7676 125 191

1401KCN 14.0 .5512 106 166 1961KCN 19.6 .7716 125 191

1411KCN 14.1 .5551 109 169 2001KCN 20.0 .7874 125 191

1451KCN 14.5 .5708 109 169

* Individually packaged

◎ : Excellent ◯ : Good

P H M K N S

Carbon Prehardened

Steels Alloy Steels Steels Hardened Steels Stainless Cast Iron Aluminum Copper Bronze CFRP Titanium

Steels

~HB225 HB225~325 HRc30~45 HRc45~55 HRc55~

◎ ◎ ○ ○ ○

192 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 193