Page 340 - YG 2019

P. 340

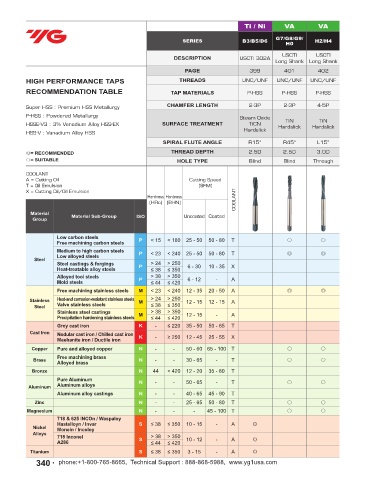

Ti / Ni VA VA VG VA VA VA VG VG VG Al

G7/G8/G9/

SERIES B3/B5/D6 H0 H2/H4 BG/BG-GB B1/B0/B2/D2 BS/BT E6/E8/E9 D3/E0 BU/BV E2/E4/E5 C0/D8

USCTI USCTI DIN Length- DIN Length- DIN Length-

DESCRIPTION USCTI 302A USCTI 302A USCTI 302A USCTI 302A USCTI 302A USCTI 302A

Long Shank Long Shank ANSI Shank ANSI Shank ANSI Shank

PAGE 399 401 402 403 404 407 408 409 412 414 415

HIGH PERFORMANCE TAPS THREADS UNC/UNF UNC/UNF UNC/UNF UNC/UN8 UNC/UNF M/MF M/MF UNC/UNF M/MF M/MF UNC/UNF

RECOMMENDATION TABLE TAP MATERIALS P-HSS P-HSS P-HSS HSSE-V3 HSSE-V3 HSSE-V3 HSSE-V3 HSSE-V3 HSSE-V3 HSSE-V3 HSSE-V3

Super HSS : Premium HSS Metallurgy CHAMFER LENGTH 2-3P 2-3P 4-5P 2-3P 2-3P 2-3P 2-3P 2-3P 2-3P 2-3P 2-3P

P-HSS : Powdered Metallurgy Steam Oxide Bright Steam Oxide Steam Oxide

TiN

Hardslick

TiN

Bright

HSSE-V3 : 3% Vanadium Alloy HSS-EX SURFACE TREATMENT TiCN Hardslick Hardslick Gold & Black Steam Oxide Steam Oxide TiCN Steam Oxide Steam Oxide TiCN Hardslick

TiN

Hardslick

Hardslick

Hardslick

Hardslick Hardslick Hardslick

HSS-V : Vanadium Alloy HSS Hardslick

SPIRAL FLUTE ANGLE R15° R45° L15° R40° R45° R45° R45° R45° R45° R45° R50°

◎= RECOMMENDED THREAD DEPTH 2.5D 2.5D 3.0D 2.5D 2.5D 2.5D 2.5D 2.5D 2.5D 2.5D 2.5D

○= SUITABLE HOLE TYPE Blind Blind Through Blind Blind Blind Blind Blind Blind Blind Blind

COOLANT

A = Cutting Oil Cutting Speed

T = Oil Emulsion (SFM)

X = Cutting Oil/Oil Emulsion

Hardness Hardness COOLANT

(HRc) (BHN)

Material Material Sub-Group

Group ISO Uncoated Coated

Low carbon steels

Free machining carbon steels P < 15 < 180 25 - 50 50 - 80 T ○ ○ ○ ○ ○

Medium to high carbon steels

Low alloyed steels P < 23 < 240 25 - 50 50 - 80 T ◎ ◎ ○ ◎ ◎ ◎ ◎ ◎ ◎

Steel

Steel castings & forgings > 24 > 250

Heat-treatable alloy steels P ≤ 38 ≤ 350 6 - 30 10 - 35 X ◎ ◎ ◎ ◎

Alloyed tool steels > 38 > 350 6 - 12 - A

Mold steels P ≤ 44 ≤ 420

Free machining stainless steels M < 23 < 240 12 - 35 20 - 50 A ◎ ◎ ◎ ◎ ◎ ◎ ○ ○ ○

Stainless Heat-and corrosion-resistant stainless steels M > 24 > 250 12 - 15 12 - 15 A ◎ ○ ○ ○

Steel Valve stainless steels ≤ 38 ≤ 350

Stainless steel castings > 38 > 350 12 - 15 - A

Precipitation hardening stainless steels M ≤ 44 ≤ 420

Grey cast iron K - ≤ 220 35 - 50 50 - 65 T

Cast Iron Nodular cast iron / Chilled cast iron

Meehanite iron / Ductile iron K - ≥ 250 12 - 45 25 - 55 X

Copper Pure and alloyed copper N - - 50 - 60 65 - 100 T ○ ○ ○ ○ ○

Free machining brass

Brass Alloyed brass N - - 30 - 65 - T ○ ○ ○ ○ ○

Bronze N 44 < 420 12 - 20 35 - 80 T ○ ○ ○

Pure Aluminum N - - 50 - 65 - T ○ ○ ○ ○ ○ ◎

Aluminum Aluminum alloys

Aluminum alloy castings N - - 40 - 65 45 - 90 T ◎ ◎

Zinc N - - 25 - 65 50 - 80 T ○ ○ ○ ○ ○

Magnesium N - - - 45 - 100 T ○ ○ ○ ○ ○

718 & 625 INCOn / Waspaloy

Hastelloyn / Invar S ≤ 38 ≤ 350 10 - 15 - A ◎ ○ ○ ○

Nickel Moneln / Incoloy

Alloys

718 Inconel > 38 > 350

A286 S ≤ 44 ≤ 420 10 - 12 - A ◎

Titanium S ≤ 38 ≤ 350 3 - 15 - A ◎

340 phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com 341