Page 342 - YG 2019

P. 342

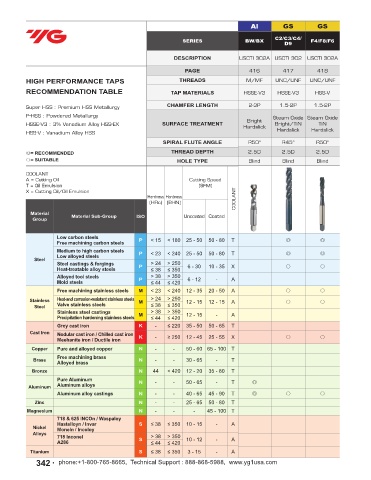

Al GS GS GS GS GS GS GS VG VG

C2/C3/C4/ T7A96/T6A96/T8A96 T7A86/T6A86/T8A86 T7D01/T8D01

SERIES BW/BX D9 F4/F8/F6 G4/G5/G6 G0/G1/G2 T7295/T6295/T8295 T7A85/T6A85/T8A85 T7D02/T8D02 M9/O1 N7/N8

DESCRIPTION USCTI 302A USCTI 302 USCTI 302A USCTI 302A DIN Length- USCTI 302 USCTI 302 USCTI USCTI 302A USCTI 302A

ANSI Shank Long Shank

PAGE 416 417 418 420 421 423 424 425 430 432

HIGH PERFORMANCE TAPS THREADS M/MF UNC/UNF UNC/UNF M/MF UNC/UNF UNC/UNF M/MF UNC/UNF UNC/UNF M/MF

RECOMMENDATION TABLE TAP MATERIALS HSSE-V3 HSSE-V3 HSS-V HSS-V HSS-V HSS HSS HSS Super HSS Super HSS

Super HSS : Premium HSS Metallurgy CHAMFER LENGTH 2-3P 1.5-2P 1.5-2P 1.5-2P 2-3P 4-5P 4-5P 4-5P 4-5P 4-5P

1.5-2P 1.5-2P 1.5-2P

P-HSS : Powdered Metallurgy Steam Oxide Steam Oxide

Bright Bright Bright Bright Bright Bright Steam Oxide Steam Oxide

HSSE-V3 : 3% Vanadium Alloy HSS-EX SURFACE TREATMENT Bright/TiN TiN TiCN TiN Steam Oxide Steam Oxide

Hardslick TiN Hardslick Hardslick

HSS-V : Vanadium Alloy HSS Hardslick Hardslick Hardslick Hardslick TiN TiN

SPIRAL FLUTE ANGLE R50° R45° R50° R50° R45° R50° R50° R50° - -

◎= RECOMMENDED THREAD DEPTH 2.5D 2.5D 2.5D 2.5D 2.5D 2.5D 2.5D 2.5D 3.0D 3.0D

○= SUITABLE HOLE TYPE Blind Blind Blind Blind Blind Blind Blind Blind Through Through

COOLANT

A = Cutting Oil Cutting Speed

T = Oil Emulsion (SFM)

X = Cutting Oil/Oil Emulsion

Hardness Hardness COOLANT

(HRc) (BHN)

Material Material Sub-Group

Group ISO Uncoated Coated

Low carbon steels

Free machining carbon steels P < 15 < 180 25 - 50 50 - 80 T ◎ ◎ ◎ ◎ ◎ ◎ ◎ ○ ○

Medium to high carbon steels

Low alloyed steels P < 23 < 240 25 - 50 50 - 80 T ◎ ◎ ◎ ◎ ◎ ◎ ◎ ◎ ◎

Steel

Steel castings & forgings > 24 > 250

Heat-treatable alloy steels P ≤ 38 ≤ 350 6 - 30 10 - 35 X ○ ○ ○ ○ ○ ○ ○ ◎ ◎

Alloyed tool steels > 38 > 350 6 - 12 - A

Mold steels P ≤ 44 ≤ 420

Free machining stainless steels M < 23 < 240 12 - 35 20 - 50 A ○ ○ ○ ○ ○ ○ ○ ◎ ◎

Stainless Heat-and corrosion-resistant stainless steels M > 24 > 250 12 - 15 12 - 15 A ○ ○ ○ ○ ○ ○ ○ ◎ ◎

Steel Valve stainless steels ≤ 38 ≤ 350

Stainless steel castings > 38 > 350 12 - 15 - A

Precipitation hardening stainless steels M ≤ 44 ≤ 420

Grey cast iron K - ≤ 220 35 - 50 50 - 65 T

Cast Iron Nodular cast iron / Chilled cast iron

Meehanite iron / Ductile iron K - ≥ 250 12 - 45 25 - 55 X ○ ○ ○ ○ ○ ○ ○

Copper Pure and alloyed copper N - - 50 - 60 65 - 100 T ○ ○

Free machining brass

Brass Alloyed brass N - - 30 - 65 - T ○ ○

Bronze N 44 < 420 12 - 20 35 - 80 T

Pure Aluminum N - - 50 - 65 - T ◎ ○ ○

Aluminum Aluminum alloys

Aluminum alloy castings N - - 40 - 65 45 - 90 T ◎ ○ ○ ○ ○ ○ ○ ○

Zinc N - - 25 - 65 50 - 80 T ○ ○

Magnesium N - - - 45 - 100 T ○ ○

718 & 625 INCOn / Waspaloy

Hastelloyn / Invar S ≤ 38 ≤ 350 10 - 15 - A

Nickel Moneln / Incoloy

Alloys

718 Inconel > 38 > 350

A286 S ≤ 44 ≤ 420 10 - 12 - A

Titanium S ≤ 38 ≤ 350 3 - 15 - A

342 phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com 343