Page 384 - YG 2019

P. 384

COMBO TAPS COMBO TAPS

TK-S / TK-C SERIES TCE-S/TCF-S/TCE-C/TCF-C SERIES

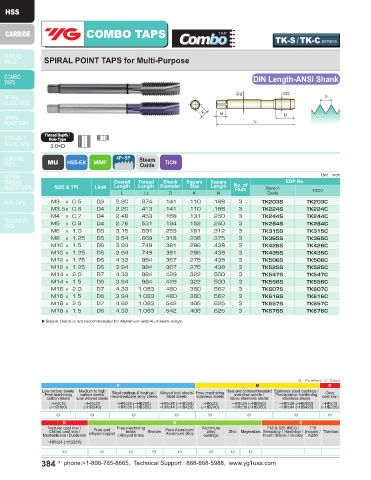

SPIRAL POINT TAPS for Multi-Purpose SPIRAL POINT TAPS for Stainless Steels

DIN Length-ANSI Shank

Thread Depth / Thread Depth /

Hole Type Hole Type

3.0×D 3.0×D

4P~5P Steam Super UNC USCTI 4P Steam

MU HSS-EX M/MF Oxide TiCN VA HSS HSS-EX UNF 302A Oxide TiCN

Unit : Inch Unit : Inch

Overall Thread Shank Square Square EDP No. Overall Thread Shank Square Square EDP No.

SIZE & TPI Limit Length Length Diameter Size Length No. of Steam SIZE & TPI Limit Length Length Diameter Size Length No. of Steam

Flute

Flute

L Lt D K kl Oxide TiCN L Lt D K kl Oxide TiCN

M3 x 0.5 D3 2.20 .374 .141 .110 .188 3 TK203S TK203C #5 - 40 UNC H2 1.94 .374 .141 .110 .188 3 TCE202S TCE202C

M3.5 x 0.6 D4 2.20 .413 .141 .110 .188 3 TK224S TK224C #5 - 40 UNC H3 1.94 .374 .141 .110 .188 3 TCE203S TCE203C

M4 x 0.7 D4 2.48 .453 .168 .131 .250 3 TK244S TK244C #6 - 32 UNC H3 2.00 .413 .141 .110 .188 3 TCE243S TCE243C

M5 x 0.8 D4 2.76 .531 .194 .152 .250 3 TK284S TK284C #8 - 32 UNC H3 2.13 .453 .168 .131 .250 3 TCE283S TCE283C

M6 x 1.0 D5 3.15 .591 .255 .191 .312 3 TK315S TK315C #10 - 24 UNC H3 2.38 .531 .194 .152 .250 3 TCE323S TCE323C

M8 x 1.25 D5 3.54 .669 .318 .238 .375 3 TK365S TK365C #10 - 32 UNF H3 2.38 .531 .194 .152 .250 3 TCE343S TCE343C

M10 x 1.5 D6 3.94 .748 .381 .286 .438 3 TK426S TK426C 1/4 - 20 UNC H3 2.50 .591 .255 .191 .312 3 TCE403S TCE403C

M10 x 1.25 D5 3.94 .748 .381 .286 .438 3 TK435S TK435C 1/4 - 20 UNC H5 2.50 .591 .255 .191 .312 3 TCE405S TCE405C

M12 x 1.75 D6 4.33 .984 .367 .275 .438 3 TK506S TK506C 1/4 - 28 UNF H3 2.50 .591 .255 .191 .312 3 TCE423S TCE423C

M12 x 1.25 D5 3.94 .984 .367 .275 .438 3 TK525S TK525C 5/16 - 18 UNC H3 2.72 .669 .318 .238 .375 3 TCE443S TCE443C

M14 x 2.0 D7 4.33 .984 .429 .322 .500 3 TK547S TK547C 5/16 - 18 UNC H5 2.72 .669 .318 .238 .375 3 TCE445S TCE445C

M14 x 1.5 D6 3.94 .984 .429 .322 .500 3 TK556S TK556C 5/16 - 24 UNF H3 2.72 .669 .318 .238 .375 3 TCE463S TCE463C

M16 x 2.0 D7 4.33 1.083 .480 .360 .562 3 TK607S TK607C 3/8 - 16 UNC H3 2.94 .748 .381 .286 .438 3 TCE483S TCE483C

M16 x 1.5 D6 3.94 1.083 .480 .360 .562 3 TK616S TK616C 3/8 - 16 UNC H5 2.94 .748 .381 .286 .438 3 TCE485S TCE485C

M18 x 2.5 D7 4.92 1.083 .542 .406 .625 3 TK657S TK657C 3/8 - 24 UNF H3 2.94 .748 .381 .286 .438 3 TCE503S TCE503C

M18 x 1.5 D6 4.33 1.083 .542 .406 .625 3 TK676S TK676C 7/16 - 14 UNC H3 3.16 .866 .323 .242 .406 3 TCE523S TCE523C

7/16 - 14 UNC H5 3.16 .866 .323 .242 .406 3 TCE525S TCE525C

▶Steam Oxide is not recommended for Aluminum and Aluminum alloys.

7/16 - 20 UNF H3 3.16 .866 .323 .242 .406 3 TCE543S TCE543C

7/16 - 20 UNF H5 3.16 .866 .323 .242 .406 3 TCE545S TCE545C

1/2 - 13 UNC H3 3.38 .984 .367 .275 .438 3 TCE563S TCE563C

1/2 - 13 UNC H5 3.38 .984 .367 .275 .438 3 TCE565S TCE565C

1/2 - 20 UNF H3 3.38 .984 .367 .275 .438 3 TCE583S TCE583C

▶Super HSS(#5~1/2) and HSS-EX(9/16~1") ▶ NEXT PAGE

◎ : Excellent ○: Good ◎ : Excellent ○: Good

P M K P M K

Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey

Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron

carbon steels Low alloyed steels Valve stainless steels stainless steels carbon steels Low alloyed steels Valve stainless steels stainless steels

~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19 ~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19

(~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220) (~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220)

◎ ◎ ◎ ◎ ◎ ◎ ◎ ◎ ○ ○ ◎

K N S K N S

Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718 Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718

Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium

Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286 Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286

~HRc24 (~HB250) ~HRc24 (~HB250)

◎ ◎ ◎ ◎ ◎ ◎ ◎ ◎

384 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 385