Page 401 - YG 2019

P. 401

SPIRAL SPIRAL

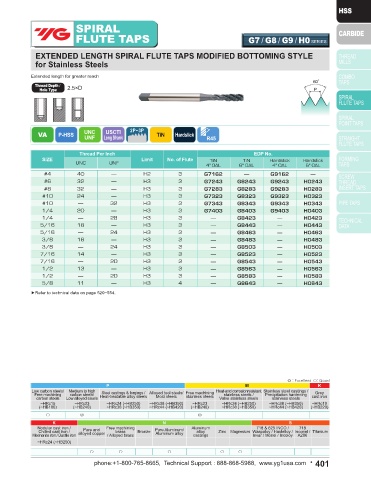

FLUTE TAPS B3 / B5 / D6 SERIES FLUTE TAPS G7 / G8 / G9 / H0 SERIES

SPIRAL FLUTE TAPS MODIFIED STYLE EXTENDED LENGTH SPIRAL FLUTE TAPS MODIFIED BOTTOMING STYLE

for Titanium Alloys & Nickel Base Alloys up to 38 ~ 45HRc for Stainless Steels

Extended length for greater reach

Thread Depth / 2.5×D Thread Depth / 2.5×D

Hole Type Hole Type

USCTI

Ti P-HSS UNC USCTI Steam TiCN P-HSS UNC USCTI 2P~3P TiN

Ni UNF 302A Oxide Hardslick R15 VA UNF Long Shank Hardslick R45

Thread Per Inch EDP No. Thread Per Inch EDP No.

SIZE Limit No. of Flute Steam SIZE Limit No. of Flute TiN TiN Hardslick Hardslick

UNC UNF TiCN Hardslick UNC UNF

Oxide 4" OAL 6" OAL 4" OAL 6" OAL

9/16 12 — H3 3 B3603 B5603 D6603 #4 40 — H2 3 G7162 — G9162 —

9/16 12 — H5 3 B3605 B5605 D6605 #6 32 — H3 3 G7243 G8243 G9243 H0243

9/16 — 18 H3 3 B3623 B5623 D6623 #8 32 — H3 3 G7283 G8283 G9283 H0283

9/16 — 18 H5 3 B3625 B5625 D6625 #10 24 — H3 3 G7323 G8323 G9323 H0323

5/8 11 — H3 4 B3643 B5643 D6643 #10 — 32 H3 3 G7343 G8343 G9343 H0343

5/8 11 — H5 4 B3645 B5645 D6645 1/4 20 — H3 3 G7403 G8403 G9403 H0403

5/8 — 18 H3 4 B3663 B5663 D6663 1/4 — 28 H3 3 — G8423 — H0423

5/8 — 18 H5 4 B3665 B5665 D6665 5/16 18 — H3 3 — G8443 — H0443

5/16 — 24 H3 3 — G8463 — H0463

3/4 10 — H3 4 B3703 B5703 D6703

3/8 16 — H3 3 — G8483 — H0483

3/4 10 — H5 4 B3705 B5705 D6705

3/4 — 16 H3 4 B3723 B5723 D6723 3/8 — 24 H3 3 — G8503 — H0503

3/4 — 16 H5 4 B3725 B5725 D6725 7/16 14 — H3 3 — G8523 — H0523

7/16 — 20 H3 3 — G8543 — H0543

▶TiN Coated Available: H9 Series 1/2 13 — H3 3 — G8563 — H0563

▶Refer to technical data on page 520~554.

1/2 — 20 H3 3 — G8583 — H0583

5/8 11 — H3 4 — G8643 — H0643

▶Refer to technical data on page 520~554.

◎ : Excellent ○: Good ◎ : Excellent ○: Good

P M K P M K

Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey

Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron

carbon steels Low alloyed steels Valve stainless steels stainless steels carbon steels Low alloyed steels Valve stainless steels stainless steels

~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19 ~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19

(~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220) (~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220)

○ ◎ ◎

K N S K N S

Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718 Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718

Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium

Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286 Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286

~HRc24 (~HB250) ~HRc24 (~HB250)

◎ ◎ ◎ ○ ○ ○ ○ ○

400 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 401