Page 403 - YG 2019

P. 403

SPIRAL SPIRAL

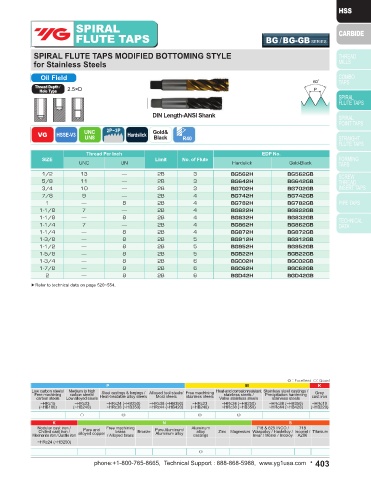

FLUTE TAPS H2 / H4 SERIES FLUTE TAPS BG / BG-GB SERIES

EXTENDED LENGTH SPIRAL FLUTE TAPS MODIFIED BOTTOMING STYLE SPIRAL FLUTE TAPS MODIFIED BOTTOMING STYLE

LEFT HAND SPIRAL FLUTE, RIGHT HAND CUT for Stainless Steels

Left hand spiral, right hand cut. Reduces chip packing in deep holes Maximum. Tapping Depth is 50% Deeper than Standard USCTI Taps. Oil Field

Thread Depth / 3.0×D Thread Depth / 2.5×D

Hole Type Hole Type

USCTI Long Shank

DIN Length-ANSI Shank

USCTI

VA P-HSS UNC Long Shank 4P~5P TiN Hardslick L15 VG HSSE-V3 UNC 2P~3P Hardslick Gold& R40

UN8

UNF

Black

Thread Per Inch EDP No. Thread Per Inch EDP No.

SIZE Limit Overall No. of Flute SIZE Limit No. of Flute

UNC UNF TiN Hardslick UNC UN Hardslick Gold-Black

1/4 20 — H3 6 2 H2403 H4403 1/2 13 — 2B 3 BG562H BG562GB

1/4 — 28 H3 6 3 H2423 H4423 5/8 11 — 2B 3 BG642H BG642GB

5/16 18 — H3 6 3 H2443 H4443 3/4 10 — 2B 3 BG702H BG702GB

3/8 16 — H3 6 3 H2483 H4483 7/8 9 — 2B 4 BG742H BG742GB

7/16 14 — H3 6 3 H2523 H4523 1 — 8 2B 4 BG782H BG782GB

1/2 13 — H3 6 3 H2563 H4563 1-1/8 7 — 2B 4 BG822H BG822GB

5/8 11 — H3 6 3 H2643 H4643 1-1/8 — 8 2B 4 BG832H BG832GB

1-1/4 7 — 2B 4 BG862H BG862GB

▶Refer to technical data on page 520~554.

1-1/4 — 8 2B 4 BG872H BG872GB

1-3/8 — 8 2B 5 BG912H BG912GB

1-1/2 — 8 2B 5 BG952H BG952GB

1-5/8 — 8 2B 5 BGB22H BGB22GB

1-3/4 — 8 2B 6 BGC02H BGC02GB

1-7/8 — 8 2B 6 BGC62H BGC62GB

2 — 8 2B 6 BGD42H BGD42GB

▶Refer to technical data on page 520~554.

◎ : Excellent ○: Good ◎ : Excellent ○: Good

P M K P M K

Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey

Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron

carbon steels Low alloyed steels Valve stainless steels stainless steels carbon steels Low alloyed steels Valve stainless steels stainless steels

~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19 ~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19

(~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220) (~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220)

○ ◎ ◎ ○ ◎ ◎ ◎

K N S K N S

Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718 Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718

Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium

Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286 Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286

~HRc24 (~HB250) ~HRc24 (~HB250)

○ ○ ○ ○ ○ ◎

402 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 403