Page 411 - YG 2019

P. 411

SPIRAL SPIRAL

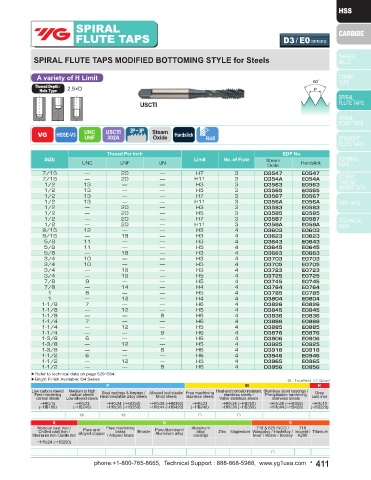

FLUTE TAPS D3 / E0 SERIES FLUTE TAPS D3 / E0 SERIES

SPIRAL FLUTE TAPS MODIFIED BOTTOMING STYLE for Steels SPIRAL FLUTE TAPS MODIFIED BOTTOMING STYLE for Steels

A variety of H Limit A variety of H Limit

Thread Depth / 2.5×D Thread Depth / 2.5×D

Hole Type Hole Type

USCTI USCTI

VG HSSE-V3 UNC USCTI Steam Hardslick R45 VG HSSE-V3 UNC USCTI Steam Hardslick R45

UNF

Oxide

302A

UNF

302A

Oxide

Thread Per Inch EDP No. Thread Per Inch EDP No.

SIZE Limit No. of Flute Steam SIZE Limit No. of Flute Steam

UNC UNF UN Hardslick UNC UNF UN Hardslick

Oxide Oxide

1/4 — 28 — H2 3 D3422 E0422 7/16 — 20 — H7 3 D3547 E0547

1/4 — 28 — H3 3 D3423 E0423 7/16 — 20 — H11 3 D354A E054A

1/4 — 28 — H4 3 D3424 E0424 1/2 13 — — H3 3 D3563 E0563

1/4 — 28 — H5 3 D3425 E0425 1/2 13 — — H5 3 D3565 E0565

1/4 — 28 — H7 3 D3427 E0427 1/2 13 — — H7 3 D3567 E0567

1/4 — 28 — H11 3 D342A E042A 1/2 13 — — H11 3 D356A E056A

5/16 18 — — H2 3 D3442 E0442 1/2 — 20 — H3 3 D3583 E0583

5/16 18 — — H3 3 D3443 E0443 1/2 — 20 — H5 3 D3585 E0585

5/16 18 — — H5 3 D3445 E0445 1/2 — 20 — H7 3 D3587 E0587

5/16 18 — — H7 3 D3447 E0447 1/2 — 20 — H11 3 D358A E058A

5/16 18 — — H11 3 D344A E044A 9/16 12 — — H3 4 D3603 E0603

5/16 — 24 — H2 3 D3462 E0462 9/16 — 18 — H3 4 D3623 E0623

5/16 — 24 — H3 3 D3463 E0463 5/8 11 — — H3 4 D3643 E0643

5/16 — 24 — H4 3 D3464 E0464 5/8 11 — — H5 4 D3645 E0645

5/16 — 24 — H5 3 D3465 E0465 5/8 — 18 — H3 4 D3663 E0663

5/16 — 24 — H6 3 D3466 E0466 3/4 10 — — H3 4 D3703 E0703

5/16 — 24 — H7 3 D3467 E0467 3/4 10 — — H5 4 D3705 E0705

5/16 — 24 — H11 3 D346A E046A 3/4 — 16 — H3 4 D3723 E0723

3/8 16 — — H2 3 D3482 E0482 3/4 — 16 — H5 4 D3725 E0725

3/8 16 — — H3 3 D3483 E0483 7/8 9 — — H5 4 D3745 E0745

3/8 16 — — H5 3 D3485 E0485 7/8 — 14 — H4 4 D3764 E0764

3/8 16 — — H7 3 D3487 E0487 1 8 — — H5 4 D3785 E0785

3/8 16 — — H11 3 D348A E048A 1 — 12 — H4 4 D3804 E0804

3/8 — 24 — H2 3 D3502 E0502 1-1/8 7 — — H6 4 D3826 E0826

3/8 — 24 — H3 3 D3503 E0503 1-1/8 — 12 — H5 4 D3845 E0845

3/8 — 24 — H4 3 D3504 E0504 1-1/8 — — 8 H6 4 D3836 E0836

3/8 — 24 — H5 3 D3505 E0505 1-1/4 7 — — H6 4 D3866 E0866

3/8 — 24 — H7 3 D3507 E0507 1-1/4 — 12 — H5 4 D3885 E0885

3/8 — 24 — H11 3 D350A E050A 1-1/4 — — 8 H6 4 D3876 E0876

7/16 14 — — H3 3 D3523 E0523 1-3/8 6 — — H6 4 D3906 E0906

7/16 14 — — H5 3 D3525 E0525 1-3/8 — 12 — H5 4 D3925 E0925

7/16 14 — — H7 3 D3527 E0527 1-3/8 — — 8 H6 4 D3916 E0916

7/16 14 — — H11 3 D352A E052A 1-1/2 6 — — H6 4 D3946 E0946

7/16 — 20 — H3 3 D3543 E0543 1-1/2 — 12 — H5 4 D3965 E0965

7/16 — 20 — H5 3 D3545 E0545 1-1/2 — — 8 H6 4 D3956 E0956

▶Refer to technical data on page 520~554. ▶ NEXT PAGE ▶Refer to technical data on page 520~554.

▶Bright Finish Available: D4 Series ◎ : Excellent ○: Good ▶Bright Finish Available: D4 Series ◎ : Excellent ○: Good

P M K P M K

Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey

Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron

carbon steels Low alloyed steels Valve stainless steels stainless steels carbon steels Low alloyed steels Valve stainless steels stainless steels

~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19 ~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19

(~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220) (~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220)

◎ ◎ ○ ○ ◎ ◎ ○ ○

K N S K N S

Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718 Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718

Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium

Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286 Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286

~HRc24 (~HB250) ~HRc24 (~HB250)

○ ○

410 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 411