Page 415 - YG 2019

P. 415

SPIRAL SPIRAL

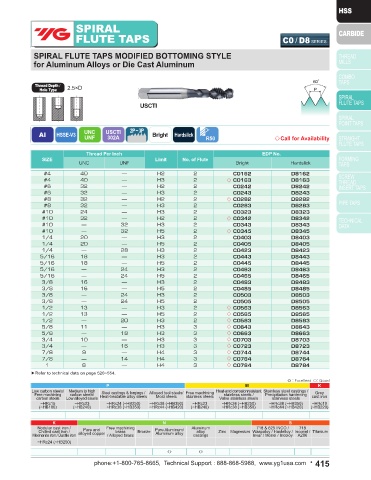

FLUTE TAPS E2 / E4 / E5 SERIES FLUTE TAPS C0 / D8 SERIES

SPIRAL FLUTE TAPS MODIFIED BOTTOMING STYLE

SPIRAL FLUTE TAPS MODIFIED BOTTOMING STYLE for Steels

for Aluminum Alloys or Die Cast Aluminum

Thread Depth / 2.5×D Thread Depth / 2.5×D

Hole Type Hole Type

DIN Length-ANSI Shank USCTI

M

VG HSSE-V3 MF Steam TiCN Hardslick R45 AI HSSE-V3 UNC USCTI Bright Hardslick R50 ◇Call for Availability

UNF

302A

Oxide

EDP No. Thread Per Inch EDP No.

SIZE Pitch Limit No. of Flute Steam SIZE Limit No. of Flute

Oxide TiCN Hardslick UNC UNF Bright Hardslick

M3 0.5 D3 3 E2203 E4203 E5203 #4 40 — H2 2 C0162 D8162

M3.5 0.6 D4 3 E2224 E4224 E5224 #4 40 — H3 2 ◇ C0163 D8163

M4 0.7 D4 3 E2244 E4244 E5244 #6 32 — H2 2 C0242 D8242

#6 32 — H3 2 C0243 D8243

M5 0.8 D4 3 E2284 E4284 E5284 #8 32 — H2 2 ◇ C0282 D8282

M6 1.0 D5 3 E2315 E4315 E5315 #8 32 — H3 2 C0283 D8283

M7 1.0 D5 3 E2345 E4345 E5345 #10 24 — H3 2 C0323 D8323

M8 1.25 D5 3 E2365 E4365 E5365 #10 32 — H2 2 ◇ C0342 D8342

M8 1.0 D5 3 E2375 E4375 E5375 #10 — 32 H3 2 C0343 D8343

M10 1.5 D6 3 E2426 E4426 E5426 #10 — 32 H5 2 ◇ C0345 D8345

M10 1.25 D5 3 E2435 E4435 E5435 1/4 20 — H3 2 C0403 D8403

—

M12 1.75 D6 3 E2506 E4506 E5506 1/4 20 28 H5 2 C0405 D8405

D8423

1/4

—

H3

2

C0423

M12 1.25 D5 3 E2525 E4525 E5525 5/16 18 — H3 2 C0443 D8443

M14 2.0 D7 3 E2547 E4547 E5547 5/16 18 — H5 2 C0445 D8445

M14 1.5 D6 3 E2556 E4556 E5556 5/16 — 24 H3 2 C0463 D8463

M16 2.0 D7 3 E2607 E4607 E5607 5/16 — 24 H5 2 C0465 D8465

M16 1.5 D6 3 E2616 E4616 E5616 3/8 16 — H3 2 C0483 D8483

M18 2.5 D7 4 E2657 E4657 E5657 3/8 16 — H5 2 C0485 D8485

M18 1.5 D6 4 E2676 E4676 E5676 3/8 — 24 H3 2 C0503 D8503

3/8 — 24 H5 2 C0505 D8505

▶Refer to technical data on page 520~554. 1/2 13 — H3 2 ◇ C0563 D8563

1/2 13 — H5 2 ◇ C0565 D8565

1/2 — 20 H3 2 ◇ C0583 D8583

5/8 11 — H3 3 ◇ C0643 D8643

5/8 — 18 H3 3 ◇ C0663 D8663

3/4 10 — H3 3 ◇ C0703 D8703

3/4 — 16 H3 3 ◇ C0723 D8723

7/8 9 — H4 3 ◇ C0744 D8744

7/8 — 14 H4 3 ◇ C0764 D8764

1 8 — H4 3 ◇ C0784 D8784

▶Refer to technical data on page 520~554.

◎ : Excellent ○: Good ◎ : Excellent ○: Good

P M K P M K

Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey Low carbon steels/ Medium to high Steel castings & forgings / Alloyed tool steels/ Free machining Heat-and corrosionresistant Stainless steel castings / Grey

Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron Free machining carbon steels/ Heat-treatable alloy steels Mold steels stainless steels stainless steels / Precipitation hardening cast iron

carbon steels Low alloyed steels Valve stainless steels stainless steels carbon steels Low alloyed steels Valve stainless steels stainless steels

~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19 ~HRc15 ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc23 ~HRc24 (~HB250) ~HRc38 (~HB350) ~HRc19

(~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220) (~HB180) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB240) ~HRc38 (~HB350) ~HRc44 (~HB420) (~HB220)

◎ ◎ ○ ○

K N S K N S

Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718 Nodular cast iron / Pure and Free machining Pure Aluminum/ Aluminum 718 & 625 INCO / 718

Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium Chilled cast iron / brass Bronze alloy Zinc Magnesium Waspaloy / Hastelloy / Inconel / Titanium

Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286 Meehanite iron / Ductile iron alloyed copper / Alloyed brass Aluminum alloy castings Invar / Monel / Incoloy A286

~HRc24 (~HB250) ~HRc24 (~HB250)

○ ◎ ◎

414 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 415