Page 554 - YG 2019

P. 554

TECHNICAL

DATA

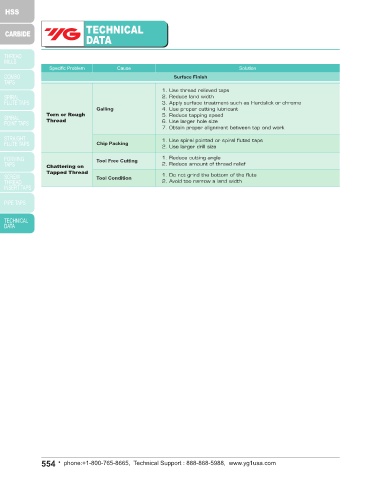

Specific Problem Cause Solution

Surface Finish

1. Use thread relieved taps MILLING

2. Reduce land width MILLING

3. Apply surface treatment such as Hardslick or chrome

Galling 4. Use proper cutting lubricant

Torn or Rough 5. Reduce tapping speed

TOOLS

Thread 6. Use larger hole size

7. Obtain proper alignment between tap and work

1. Use spiral pointed or spiral fluted taps TOOLS

Chip Packing

2. Use larger drill size

1. Reduce cutting angle

Tool Free Cutting

Chattering on 2. Reduce amount of thread relief

Tapped Thread 1. Do not grind the bottom of the flute

Tool Condition

2. Avoid too narrow a land width

CBN END MILLS

i-Xmills, CARBIDE INSERT END MILLS

i-SMART, MODULAR CARBIDE HEAD END MILLS

X5070 NANO SOLID CARBIDE END MILLS

4G MILL SOLID CARBIDE END MILLS

X-POWER SOLID CARBIDE END MILLS

JET-POWER SOLID CARBIDE & HSS-PM END MILLS

TitaNox-POWER SOLID CARBIDE END MILLS

V7 PLUS A SOLID CARBIDE END MILLS

V7 Mill INOX SOLID CARBIDE END MILLS

ALU-POWER HPC SOLID CARBIDE END MILLS

ALU-POWER SOLID CARBIDE & HSS-PM END MILLS

D-POWER GRAPHITE DIAMOND COATED SOLID CARBIDE END MILLS

D-POWER CFRP DIAMOND COATED SOLID CARBIDE END MILLS

SOLID CARBIDE ROUTERS CFRP

STANDARD CARBIDE END MILLS

ONLY ONE COATED PM60 END MILLS

SINE-POWER HSS END MILLS

TANK-POWER HSS-PM END MILLS

COBALT & HSS END MILLS

TECHNICAL DATA

554 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com