Page 795 - YG 2019

P. 795

4G MILL 4G MILL

END MILLS GAE53 SERIES FLAT SHANK END MILLS

HSS-PM, 4&5 FLUTE MULTIPLE HELIX SHORT LENGTH ROUGHING

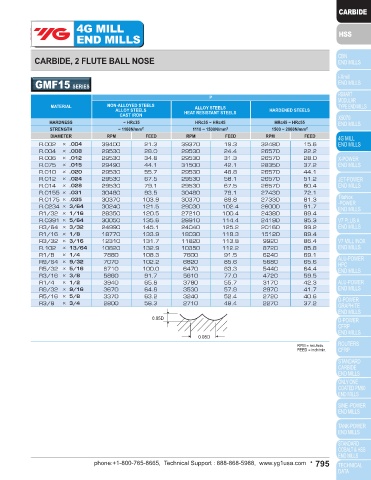

CORNER RADIUS CARBIDE, 2 FLUTE BALL NOSE

▶ Unique flute design for excellent chip evacuation and vibration reduction.

▶ Optimal roughing tooth profile to reduce cutting forces.

▶ Special tool geometry for high feed rate and heavy cutting. GMF15 SERIES

▶ Strong end tooth design for plunge and pocket milling.

▶ Custom engineered coating to allow long tool life and excellent chip evacuation. P

R R MATERIAL NON-ALLOYED STEELS ALLOY STEELS HARDENED STEELS

ALLOY STEELS

↙ CAST IRON HEAT RESISTANT STEELS

D2 D1 HARDNESS ~ HRc35 HRc35 ~ HRc45 HRc45 ~ HRc55

L1 STRENGTH ~ 1100N/mm 2 1110 ~ 1500N/mm 2 1500 ~ 2000N/mm 2

L2 DIAMETER RPM FEED RPM FEED RPM FEED

R.002 × .004 39400 21.3 39370 19.3 32480 15.6

R.004 × .008 29530 28.0 29530 24.4 26570 22.2

44º/45º P.845 ◇ Call for Availability R.006 × .012 29530 34.8 29530 31.3 26570 28.0

5 Flute, 44°/44.5°/45° R.075 × .015 29490 44.1 31500 42.1 28350 37.2

Unit : mm R.010 × .020 29530 55.7 29530 48.8 26570 44.1

Shank

Mill

EDP No. Corner Diameter Diameter Length Overall No. of R.012 × .024 29530 67.5 29530 58.1 26570 51.2

Length

of Cut

Radius

Metric Inch Flute R.014 × .028 29530 79.1 29530 67.5 26570 60.4

FLAT R D2(h6) L1 L2 R.0155 × .031 30480 93.5 30480 79.1 27430 72.1

D1(js12)

R.0175 × .035 30370 103.9 30370 89.8 27330 81.3

GAE53060 R0.5 6.0 .2362 6 13 57 4 R.0234 × 3/64 30240 121.5 29030 102.4 26000 91.7

GAE53070 R0.5 7.0 .2756 10 16 66 4 R1/32 × 1/16 28350 120.5 27210 100.4 24380 89.4

GAE53080 R0.5 8.0 .3150 10 19 69 4 R.0391 × 5/64 30050 135.6 28910 114.4 24190 95.3

GAE53090 R0.5 9.0 .3543 10 19 69 4 R3/64 × 3/32 24990 145.1 24040 125.2 20160 99.2

GAE53100 R0.5 10.0 .3937 10 22 72 4 R1/16 × 1/8 18770 133.9 18030 118.3 15120 89.4

GAE53120 R0.5 12.0 .4724 12 26 83 4 R3/32 × 3/16 12310 131.7 11820 113.8 9920 86.4

GAE53140 R1.0 14.0 .5512 16 26 83 5 R.102 × 13/64 10820 132.9 10350 112.2 8720 85.8

GAE53160 R1.0 16.0 .6299 16 32 92 5 R1/8 × 1/4 7880 108.3 7600 91.5 6240 69.1

GAE53180 R1.0 18.0 .7087 20 32 92 5 R9/64 × 9/32 7070 102.2 6820 85.6 5680 65.6

GAE53200 R1.0 20.0 .7874 20 38 104 5 R5/32 × 5/16 6710 100.0 6470 83.3 5440 64.4

R3/16 × 3/8 5860 91.7 5610 77.0 4720 59.5

Tolerances according to DIN 7160 & 7161 R1/4 × 1/2 3940 65.8 3780 55.7 3170 42.3

Tolerance range in ㎛ R9/32 × 9/16 3670 64.8 3530 57.9 2970 41.7

Nominal-Diameter in ㎜ R5/16 × 5/8 3370 63.2 3240 52.4 2720 40.6

from 1 to 3 over 3 to 6 over 6 to 10 over 10 to 18 over 18 to 30 over 30 to 50 R3/8 × 3/4 2800 58.3 2710 48.4 2270 37.2

js12 ± 50 ± 60 ± 75 ± 90 ± 105 ± 125

h6 0 0 0 0 0 0 0.05D

- 9

- 8

- 6

- 16

- 13

- 11

0.08D

RPM = rev./min.

FEED = inch/min.

◎ : Excellent ◯ : Good

P H M K N S

Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Steels

Iron

~HB225 HB225~325 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

◎ ◎ ○ ◎ ◎ ○

794 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 795