Page 799 - YG 2019

P. 799

4G MILL 4G MILL

END MILLS RECOMMENDED CUTTING CONDITIONS END MILLS RECOMMENDED CUTTING CONDITIONS

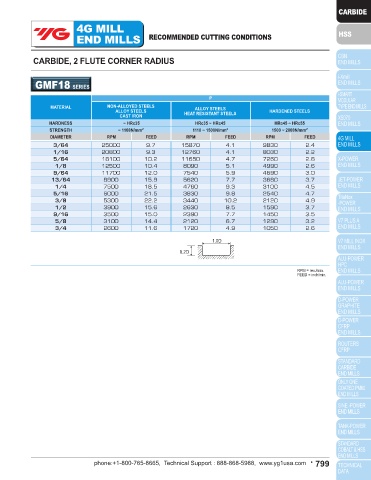

CARBIDE, 2 FLUTE BALL NOSE WITH NECK CARBIDE, 2 FLUTE CORNER RADIUS

GMF16 SERIES GMF18 SERIES

P P

MATERIAL NON-ALLOYED STEELS ALLOY STEELS MATERIAL NON-ALLOYED STEELS ALLOY STEELS

ALLOY STEELS HEAT RESISTANT STEELS HARDENED STEELS ALLOY STEELS HEAT RESISTANT STEELS HARDENED STEELS

CAST IRON CAST IRON

HARDNESS ~ HRc35 HRc35 ~ HRc45 HRc45 ~ HRc55 HARDNESS ~ HRc35 HRc35 ~ HRc45 HRc45 ~ HRc55

STRENGTH ~ 1100N/mm 2 1110 ~ 1500N/mm 2 1500 ~ 2000N/mm 2 STRENGTH ~ 1100N/mm 2 1110 ~ 1500N/mm 2 1500 ~ 2000N/mm 2

DIA. LBS RPM FEED Ap(inch) RPM FEED Ap(inch) RPM FEED Ap(inch) DIAMETER RPM FEED RPM FEED RPM FEED

1/4 1-3/16 6140 70.7 .0157 5860 59.5 .0131 5200 49.4 .0087 3/64 25000 9.7 15870 4.1 9830 2.4

5/16 1 4890 71.5 .0197 4640 59.5 .0164 4030 50.8 .0109 1/16 20800 9.3 12760 4.1 8030 2.2

5/16 1-3/8 4890 71.5 .0197 4640 59.5 .0164 4030 50.8 .0109 5/64 18100 10.2 11650 4.7 7260 2.8

3/8 1-3/16 4040 68.1 .0236 3860 57.9 .0197 3360 49.6 .0131 1/8 12500 10.4 8090 5.1 4990 2.6

3/8 1-3/16 4040 68.1 .0236 3860 57.9 .0197 3360 49.6 .0131 9/64 11700 12.0 7540 5.9 4690 3.0

3/8 1-1/2 4040 68.1 .0236 3860 57.9 .0197 3360 49.6 .0131 13/64 8900 15.9 5620 7.7 3680 3.7

1/2 1-1/4 3020 56.5 .0450 2880 48.4 .0375 2500 40.9 .0250 1/4 7500 18.5 4760 9.3 3100 4.5

1/2 1-1/4 3020 56.5 .0450 2880 48.4 .0375 2500 40.9 .0250 5/16 6000 21.5 3830 9.8 2540 4.7

3/8 5300 22.2 3440 10.2 2120 4.9

1/2 3900 15.6 2630 8.5 1590 3.7

9/16 3500 15.0 2390 7.7 1450 3.5

(Depth of Cut per one pass) 5/8 3100 14.4 2120 6.7 1290 3.2

3/4 2600 11.6 1720 4.9 1050 2.6

DIA. = Diameter RPM = rev./min. 1.0D

LBS = Length Below Shank FEED = inch/min.

0.2D

RPM = rev./min.

CARBIDE, 4 FLUTE BALL NOSE FEED = inch/min.

GMF17 SERIES

P

MATERIAL NON-ALLOYED STEELS ALLOY STEELS

ALLOY STEELS HEAT RESISTANT STEELS HARDENED STEELS

CAST IRON

HARDNESS ~ HRc35 HRc35 ~ HRc45 HRc45 ~ HRc55

STRENGTH ~ 1100N/mm 2 1110 ~ 1500N/mm 2 1500 ~ 2000N/mm 2

DIAMETER RPM FEED RPM FEED RPM FEED

R1/16 × 1/8 22700 202.0 16540 144.3 15120 135.8

R3/32 × 3/16 17600 224.4 13020 152.6 12250 143.5

R1/8 × 1/4 14400 231.3 11530 167.3 10490 142.5

R5/32 × 5/16 11400 208.3 9270 157.9 8390 132.9

R3/16 × 3/8 9600 189.8 7720 142.5 6990 118.7

R1/4 × 1/2 7200 158.5 5790 118.7 5230 89.4

0.02D

0.05D

RPM = rev./min.

FEED = inch/min.

798 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 799