Page 893 - YG 2019

P. 893

X-POWER EM812 SERIES PLAIN SHANK X-POWER

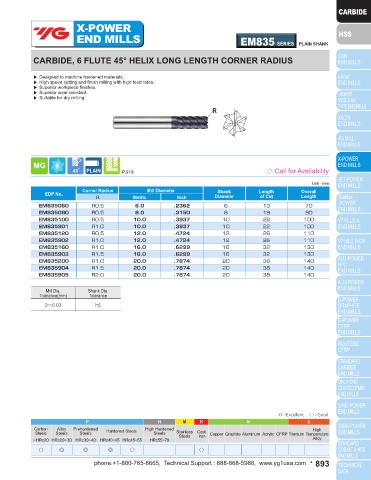

END MILLS EM834 SERIES PLAIN SHANK END MILLS EM835 SERIES PLAIN SHANK

CARBIDE, 6&8 FLUTE 45° HELIX LONG & EXTRA LONG LENGTH CARBIDE, 6 FLUTE 45° HELIX LONG LENGTH CORNER RADIUS

▶ Designed to machine hardened materials. ▶ Designed to machine hardened materials.

▶ High speed cutting and finish milling with high feed rates. ▶ High speed cutting and finish milling with high feed rates.

▶ Superior workpiece finishes. ▶ Superior workpiece finishes.

▶ Superior wear resistant. ▶ Superior wear resistant.

▶ Suitable for dry milling. ▶ Suitable for dry milling.

R

↙

P.918, 919 ◇ Call for Availability P.919 ◇ Call for Availability

EM812 Series ■ LONG LENGTH Unit : mm Unit : mm

Mill Diameter Shank Length Overall No. of Corner Radius Mill Diameter Shank Length Overall

EDP No. EDP No.

Metric Inch Diameter of Cut Length Flute R Metric Inch Diameter of Cut Length

EM812060 6.0 .2362 6 13 57 6 EM835060 R0.5 6.0 .2362 6 13 70

EM812070 7.0 .2756 8 16 63 6 EM835080 R0.5 8.0 .3150 8 19 90

EM812080 8.0 .3150 8 19 63 6 EM835100 R0.5 10.0 .3937 10 22 100

EM812090 9.0 .3543 10 19 72 6 EM835901 R1.0 10.0 .3937 10 22 100

EM812100 10.0 .3937 10 22 72 6 EM835120 R0.5 12.0 .4724 12 26 110

EM812120 12.0 .4724 12 26 83 6 EM835902 R1.0 12.0 .4724 12 26 110

EM812140 14.0 .5512 14 26 83 6 EM835160 R1.0 16.0 .6299 16 32 130

EM812901 14.0 .5512 16 26 83 6 EM835903 R1.5 16.0 .6299 16 32 130

EM812160 16.0 .6299 16 32 92 6 EM835200 R1.0 20.0 .7874 20 38 140

EM812180 18.0 .7087 18 32 92 8 EM835904 R1.5 20.0 .7874 20 38 140

EM812200 20.0 .7874 20 38 104 8 EM835905 R2.0 20.0 .7874 20 38 140

EM812250 25.0 .9843 25 44 104 8

EM834 Series ■ EXTRA LONG LENGTH Unit : mm Mill Dia. Shank Dia.

Mill Diameter Shank Length Overall No. of Tolerance(mm) Tolerance

EDP No.

Metric Inch Diameter of Cut Length Flute 0~-0.03 h6

EM834060 6.0 .2362 6 26 70 6

EM834080 8.0 .3150 8 36 90 6

EM834100 10.0 .3937 10 46 100 6

EM834120 12.0 .4724 12 56 110 6

EM834160 16.0 .6299 16 66 130 6

EM834200 20.0 .7874 20 76 140 6

EM834250 25.0 .9843 25 92 180 6

Mill Dia. Shank Dia.

Tolerance(mm) Tolerance

0~-0.03 h6

Enforced cutting edge

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Iron

Steels

Steels

Iron

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

○ ◎ ◎ ◎ ○ ○ ○ ◎ ◎ ◎ ○ ○

892 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 893