Page 896 - YG 2019

P. 896

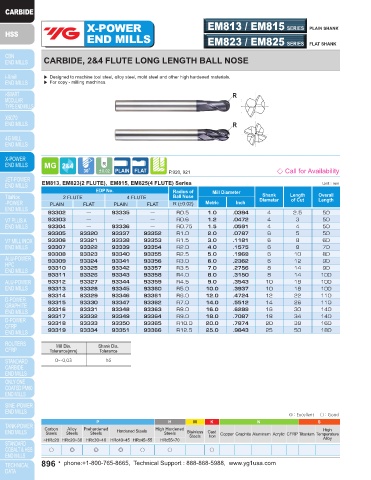

X-POWER EM813 / EM815 SERIES PLAIN SHANK X-POWER

END MILLS EM823 / EM825 SERIES FLAT SHANK END MILLS EM899 SERIES PLAIN SHANK

CARBIDE, 2&4 FLUTE LONG LENGTH BALL NOSE CARBIDE, 2 FLUTE MEDIUM LENGTH BALL NOSE

▶ Designed to machine tool steel, alloy steel, mold steel and other high hardened materials. ▶ Deep slotting milling is possible by reduced neck.

▶ For copy - milling machines. ▶ High efficiency milling is possible in deep slotting with projection of the end mill being long.

R

↙

R D3 R

↙

D2 D1

R L1

↙

L3

L2

P.920, 921 ◇ Call for Availability P.922 ◇ Call for Availability

EM813, EM823(2 FLUTE), EM815, EM825(4 FLUTE) Series Unit : mm Unit : mm

EDP No. Radius of Mill Diameter Radius of Mill Diameter Shank Length Length Overall Neck

Shank

2 FLUTE 4 FLUTE Ball Nose Diameter Length Overall EDP No. Ball Nose Metric Inch Diameter of Cut Below Shank Length Diameter

Length

of Cut

PLAIN FLAT PLAIN FLAT R (±0.02) Metric Inch R (±0.01) D1 D2 L1 L3 L2 D3

93302 — 93335 — R0.5 1.0 .0394 4 2.5 50 EM899030 R1.5 3.0 .1181 6 8 — 70 —

93303 — — — R0.6 1.2 .0472 4 3 50 EM899040 R2.0 4.0 .1575 6 8 — 70 —

93304 — 93336 — R0.75 1.5 .0591 4 4 50 EM899050 R2.5 5.0 .1969 6 12 — 80 —

93305 93320 93337 93352 R1.0 2.0 .0787 6 5 50 EM899060 R3.0 6.0 .2362 6 12 22 80 5.8

93306 93321 93338 93353 R1.5 3.0 .1181 6 8 60 EM899070 R3.5 7.0 .2756 8 14 — 90 —

93307 93322 93339 93354 R2.0 4.0 .1575 6 8 70 EM899080 R4.0 8.0 .3150 8 14 27 90 7.8

93308 93323 93340 93355 R2.5 5.0 .1969 6 10 80 EM899100 R5.0 10.0 .3937 10 18 31 100 9.8

93309 93324 93341 93356 R3.0 6.0 .2362 6 12 90 EM899120 R6.0 12.0 .4724 12 22 35 110 11.8

93310 93325 93342 93357 R3.5 7.0 .2756 8 14 90 EM899140 R7.0 14.0 .5512 12 26 — 120 —

93311 93326 93343 93358 R4.0 8.0 .3150 8 14 100 EM899160 R8.0 16.0 .6299 16 30 50 140 15.8

93312 93327 93344 93359 R4.5 9.0 .3543 10 18 100 EM899180 R9.0 18.0 .7087 16 34 — 140 —

93313 93328 93345 93360 R5.0 10.0 .3937 10 18 100 EM899200 R10.0 20.0 .7874 20 38 58 160 19.8

93314 93329 93346 93361 R6.0 12.0 .4724 12 22 110 EM899250 R12.5 25.0 .9843 25 55 75 180 24.8

93315 93330 93347 93362 R7.0 14.0 .5512 14 26 110

93316 93331 93348 93363 R8.0 16.0 .6299 16 30 140 Mill Dia. Shank Dia.

93317 93332 93349 93364 R9.0 18.0 .7087 18 34 140 Tolerance(mm) Tolerance

93318 93333 93350 93365 R10.0 20.0 .7874 20 38 160 0~-0.03 h6

93319 93334 93351 93366 R12.5 25.0 .9843 25 50 180

Mill Dia. Shank Dia.

Tolerance(mm) Tolerance

0~-0.03 h6

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Iron

Steels

Steels

Iron

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

○ ◎ ◎ ◎ ○ ○ ○ ○ ◎ ◎ ◎ ○ ○ ○

896 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 897