Page 899 - YG 2019

P. 899

X-POWER X-POWER

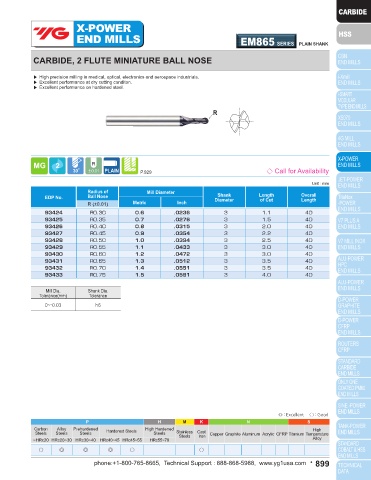

END MILLS EM838 SERIES PLAIN SHANK END MILLS EM865 SERIES PLAIN SHANK

CARBIDE, 2 FLUTE LONG REACH BALL NOSE CARBIDE, 2 FLUTE MINIATURE BALL NOSE

▶ Longer overall length than EM813 types and suitable for machining deeply located area. ▶ High precision milling in medical, optical, electronics and aerospace industrials.

▶ Excellent performance at dry cutting conditon.

▶ Excellent performance on hardened steel.

R R

↙ ↙

P.923 ◇ Call for Availability P.929 ◇ Call for Availability

Unit : mm Unit : mm

Radius of Mill Diameter Radius of Mill Diameter

Shank

Shank

EDP No. Ball Nose Diameter Length Overall EDP No. Ball Nose Diameter Length Overall

Length

of Cut

Length

of Cut

R (±0.02) Metric Inch R (±0.01) Metric Inch

EM838020 R1.0 2.0 .0787 3 6 80 93424 R0.30 0.6 .0236 3 1.1 40

EM838030 R1.5 3.0 .1181 3 8 100 93425 R0.35 0.7 .0276 3 1.5 40

EM838040 R2.0 4.0 .1575 4 8 100 93426 R0.40 0.8 .0315 3 2.0 40

EM838050 R2.5 5.0 .1969 6 10 120 93427 R0.45 0.9 .0354 3 2.2 40

EM838060 R3.0 6.0 .2362 6 10 120 93428 R0.50 1.0 .0394 3 2.5 40

EM838080 R4.0 8.0 .3150 8 14 140 93429 R0.55 1.1 .0433 3 3.0 40

EM838100 R5.0 10.0 .3937 10 18 180 93430 R0.60 1.2 .0472 3 3.0 40

EM838120 R6.0 12.0 .4724 12 22 200 93431 R0.65 1.3 .0512 3 3.5 40

EM838160 R8.0 16.0 .6299 16 30 250 93432 R0.70 1.4 .0551 3 3.5 40

EM838200 R10.0 20.0 .7874 20 38 250 93433 R0.75 1.5 .0591 3 4.0 40

Mill Dia. Shank Dia. Mill Dia. Shank Dia.

Tolerance(mm) Tolerance Tolerance(mm) Tolerance

0~-0.03 h6 0~-0.03 h6

◎ : Excellent ◯ : Good ◎ : Excellent ◯ : Good

P H M K N S P H M K N S

Carbon Alloy Prehardened High Hardened High Carbon Alloy Prehardened High Hardened High

Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature Steels Steels Steels Hardened Steels Steels Stainless Cast Copper Graphite Aluminum Acrylic CFRP Titanium Temperature

Iron

Iron

Steels

Steels

~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy ~HRc20 HRc20~30 HRc30~40 HRc40~45 HRc45~55 HRc55~70 Alloy

○ ◎ ◎ ◎ ○ ○ ○ ○ ◎ ◎ ◎ ○ ○

898 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 899