Page 929 - YG 2019

P. 929

X-POWER X-POWER

END MILLS RECOMMENDED CUTTING CONDITIONS END MILLS RECOMMENDED CUTTING CONDITIONS

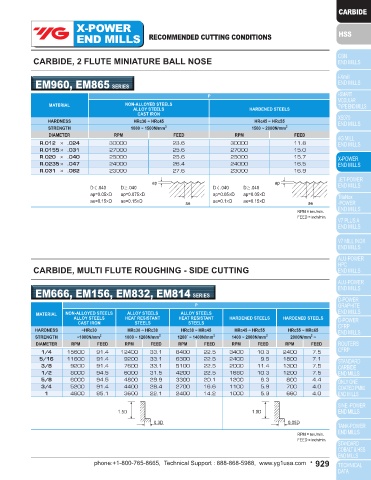

CARBIDE, 4 FLUTE BALL NOSE - MMC CARBIDE, 2 FLUTE MINIATURE BALL NOSE

RECOMMENDED EM960, EM865 SERIES

ae P

CUTTING MATERIAL NON-ALLOYED STEELS

ap CONDITIONS ALLOY STEELS HARDENED STEELS

CAST IRON

HARDNESS HRc30 ~ HRc45 HRc45 ~ HRc55

STRENGTH 1000 ~ 1500N/mm 2 1500 ~ 2000N/mm 2

DIAMETER RPM FEED RPM FEED

R.012 × .024 30000 23.6 30000 11.8

▶ ap=0.02×D1 R.0155 × .031

▶ ae=0.05×D1 27000 25.6 27000 15.0

R.020 × .040 25000 25.6 25000 15.7

R.0235 × .047 24000 26.4 24000 16.5

R.031 × .062 23000 27.6 23000 16.9

ap ap

D<.040 D≧.040 D<.040 D≧.040

EM093, EM097, EM673, EM864 SERIES ap=0.05×D ap=0.075×D ap=0.05×D ap=0.05×D

ae=0.15×D ae=0.15×D ae ae=0.1×D ae=0.15×D ae

■ NORMAL SPEED

RPM = rev./min.

P FEED = inch/min.

MATERIAL NON-ALLOYED STEELS ALLOYED STEELS

ALLOY STEELS HEAT RESISTANT HARDENED STEELS

CAST IRON STEELS

HARDNESS ~HRc30 HRc30 ~ HRc40 HRc45 ~ HRc65

STRENGTH ~1000N/mm 2 1000 ~ 1250N/mm 2 1500N/mm 2

DIAMETER RPM FEED RPM FEED RPM FEED

R3/32 × 3/16 21000 157.5 20000 157.5 7000 55.1

R1/8 × 1/4 17000 157.5 16000 137.8 6000 51.2 CARBIDE, MULTI FLUTE ROUGHING - SIDE CUTTING

R5/32 × 5/16 13000 137.8 12000 118.1 4500 43.3

R3/16 × 3/8 10500 118.1 10000 98.4 3500 39.4

R1/4 × 1/2 9000 110.2 8000 98.4 3000 37.4

R5/16 × 5/8 6000 110.2 5500 86.6 2000 31.5 EM666, EM156, EM832, EM814 SERIES

RPM = rev./min. P

FEED = inch/min.

MATERIAL NON-ALLOYED STEELS ALLOY STEELS ALLOY STEELS

ALLOY STEELS HEAT RESISTANT HEAT RESISTANT HARDENED STEELS HARDENED STEELS

CAST IRON STEELS STEELS

■ HIGH SPEED HARDNESS ~HRc30 HRc30 ~ HRc38 HRc38 ~ HRc45 HRc45 ~ HRc55 HRc55 ~ HRc65

2

P STRENGTH ~1000N/mm 2 1000 ~ 1200N/mm 2 1200` ~ 1400N/mm 2 1400 ~ 2000N/mm 2 2000N/mm ~

MATERIAL NON-ALLOYED STEELS ALLOYED STEELS DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED

ALLOY STEELS HEAT RESISTANT HARDENED STEELS 1/4 15600 91.4 12400 33.1 8400 22.5 3400 10.3 2400 7.5

CAST IRON STEELS 5/16

9.5

HARDNESS ~HRc30 HRc30 ~ HRc40 HRc45 ~ HRc65 3/8 11600 91.4 9200 33.1 6300 22.5 2400 11.4 1800 7.1

9200

91.4

7600

22.5

2000

1300

33.1

7.5

5100

STRENGTH ~1000N/mm 2 1000 ~ 1250N/mm 2 1500N/mm 2 1/2 8000 94.5 6000 31.5 4200 22.5 1680 10.3 1200 7.5

DIAMETER RPM FEED RPM FEED RPM FEED

5/8 6000 94.5 4800 29.9 3300 20.1 1200 6.3 800 4.4

R3/32 × 3/16 28000 220.5 27000 208.7 11000 82.7 3/4 5200 91.4 4400 28.4 2700 16.6 1100 5.9 700 4.0

R1/8 × 1/4 23000 200.1 22000 192.9 9000 74.8 1 4800 85.1 3600 22.1 2400 14.2 1000 5.9 660 4.0

R5/32 × 5/16 18000 181.1 17000 169.3 7000 66.9

R3/16 × 3/8 14000 153.5 13000 145.7 5000 55.1

R1/4 × 1/2 12000 145.7 11000 137.8 4500 51.2 1.5D 1.0D

R5/16 × 5/8 9000 122.0 8000 118.1 3300 43.3

0.3D 0.05D

RPM = rev./min.

FEED = inch/min. RPM = rev./min.

FEED = inch/min.

928 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 929