Page 933 - YG 2019

P. 933

X-POWER X-POWER

END MILLS RECOMMENDED CUTTING CONDITIONS END MILLS RECOMMENDED CUTTING CONDITIONS

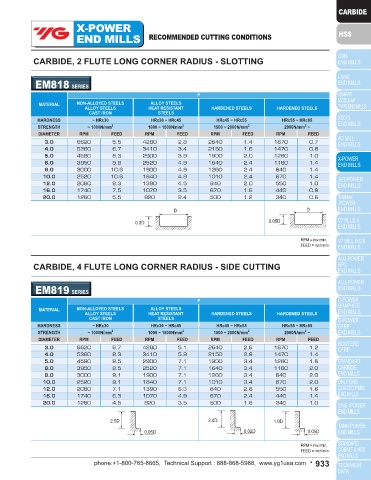

CARBIDE, 3 FLUTE - SLOTTING CARBIDE, 2 FLUTE LONG CORNER RADIUS - SLOTTING

EM895 SERIES EM818 SERIES

P M P

MATERIAL NON-ALLOYED STEELS ALLOY STEELS MATERIAL NON-ALLOYED STEELS ALLOY STEELS

ALLOY STEELS HEAT RESISTANT HARDENED STEELS HARDENED STEELS STAINLESS STEELS ALLOY STEELS HEAT RESISTANT HARDENED STEELS HARDENED STEELS

CAST IRON STEELS CAST IRON STEELS

HARDNESS ~ HRc30 HRc30 ~ HRc45 HRc45 ~ HRc55 HRc55 ~ HRc65 HARDNESS ~ HRc30 HRc30 ~ HRc45 HRc45 ~ HRc55 HRc55 ~ HRc65

2

2

STRENGTH ~ 1000N/mm 2 1000 ~ 1500N/mm 2 1500 ~ 2000N/mm 2 2000N/mm ~ STRENGTH ~ 1000N/mm 2 1000 ~ 1500N/mm 2 1500 ~ 2000N/mm 2 2000N/mm ~

DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED

2.0 11560 6.7 7560 4.3 5040 1.2 6300 3.2 3.0 6620 5.5 4280 2.8 2640 1.4 1870 0.7

3.0 8920 7.5 5560 5.1 3360 1.4 1900 1.6 4620 4.3 4.0 5360 6.7 3410 3.4 2150 1.6 1470 0.8

4.0 7560 10.6 4620 6.3 2940 1.4 1480 1.4 3880 5.1 5.0 4580 8.3 2900 3.9 1900 2.0 1260 1.0

5.0 6300 11.0 3780 6.7 2320 1.8 1260 1.4 3160 5.5 6.0 3950 9.8 2520 4.9 1640 2.4 1160 1.4

6.0 5560 12.2 3360 7.9 2000 2.0 1100 1.4 2840 6.3 8.0 3000 10.6 1900 4.9 1260 2.4 840 1.4

8.0 4200 13.4 2520 7.1 1680 2.6 840 1.4 2100 6.3 10.0 2520 10.6 1640 4.9 1010 2.4 670 1.4

10.0 3260 11.8 2000 5.5 1360 2.2 680 1.2 1680 5.7 12.0 2060 8.3 1390 4.5 840 2.0 550 1.0

12.0 2740 9.8 1680 4.7 1160 2.0 560 1.2 1360 4.7 16.0 1740 7.5 1070 3.5 670 1.6 440 0.8

16.0 2200 7.9 1360 3.9 900 1.4 440 0.8 1060 3.9 20.0 1260 5.5 820 2.4 500 1.2 340 0.6

18.0 1940 6.9 1210 3.4 790 1.2 380 0.8 950 3.4

20.0 1680 5.9 1060 2.8 680 1.0 320 0.8 840 2.8 D D

0.5D 0.05D 0.5D 0.3D 0.05D

(up to Ø3:0.2D) D D (up to Ø3:0.2D) D RPM = rev./min.

FEED = inch/min.

RPM = rev./min. FEED = inch/min.

CARBIDE, 3 FLUTE - SIDE CUTTING CARBIDE, 4 FLUTE LONG CORNER RADIUS - SIDE CUTTING

EM895 SERIES EM819 SERIES

P M P

MATERIAL NON-ALLOYED STEELS ALLOY STEELS MATERIAL NON-ALLOYED STEELS ALLOY STEELS

ALLOY STEELS HEAT RESISTANT HARDENED STEELS HARDENED STEELS STAINLESS STEELS ALLOY STEELS HEAT RESISTANT HARDENED STEELS HARDENED STEELS

CAST IRON STEELS CAST IRON STEELS

HARDNESS ~ HRc30 HRc30 ~ HRc45 HRc45 ~ HRc55 HRc55 ~ HRc65 HARDNESS ~ HRc30 HRc30 ~ HRc45 HRc45 ~ HRc55 HRc55 ~ HRc65

2

STRENGTH ~ 1000N/mm 2 1000 ~ 1500N/mm 2 1500 ~ 2000N/mm 2 2000N/mm ~ STRENGTH ~ 1000N/mm 2 1000 ~ 1500N/mm 2 1500 ~ 2000N/mm 2 2000N/mm ~

2

DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED

2.0 11560 8.3 7560 5.5 5040 1.2 6300 4.5 3.0 6620 6.7 4280 5.1 2640 2.6 1870 1.2

3.0 8920 9.5 5560 5.9 3360 1.6 1900 1.8 4620 4.9 4.0 5360 8.3 3410 5.9 2150 2.8 1470 1.4

4.0 7560 16.9 4620 10.2 2940 1.8 1480 1.8 3880 8.3 5.0 4580 8.5 2900 7.1 1900 3.4 1260 1.6

5.0 6300 17.7 3780 10.6 2320 2.2 1260 1.8 3160 9.1 6.0 3950 8.5 2520 7.1 1640 3.4 1160 2.0

6.0 5560 19.7 3360 12.2 2000 2.4 1100 1.8 2840 9.8 8.0 3000 9.1 1900 7.1 1260 3.4 840 2.0

8.0 4200 20.9 2520 11.4 1680 3.2 840 1.8 2100 10.4 10.0 2520 9.1 1640 7.1 1010 3.4 670 2.0

10.0 3260 18.1 2000 9.1 1360 2.8 680 1.4 1680 9.1 12.0 2060 7.1 1390 6.3 840 2.8 550 1.6

12.0 2740 15.4 1680 7.5 1160 2.4 560 1.4 1360 7.1 16.0 1740 6.3 1070 4.9 670 2.4 440 1.4

16.0 2200 12.2 1360 5.9 900 1.8 440 0.8 1060 5.9 20.0 1260 4.5 820 3.5 500 1.8 340 1.0

18.0 1940 11.0 1210 5.3 790 1.4 380 0.8 950 5.1

20.0 1680 9.5 1060 4.7 680 1.2 320 0.8 840 4.5

2.5D 2.0D 1.0D

1.0D 0.05D 0.02D 0.05D

0.05D RPM = rev./min.

RPM = rev./min. FEED = inch/min. FEED = inch/min.

932 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 933