Page 930 - YG 2019

P. 930

X-POWER X-POWER

END MILLS RECOMMENDED CUTTING CONDITIONS END MILLS RECOMMENDED CUTTING CONDITIONS

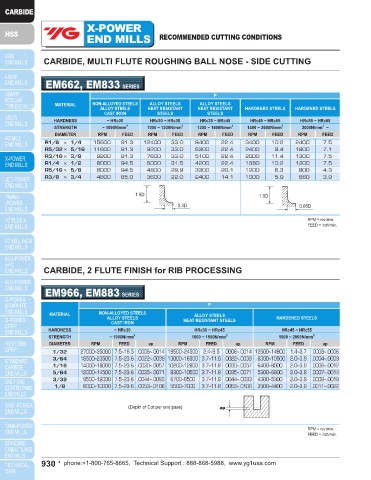

CARBIDE, MULTI FLUTE ROUGHING BALL NOSE - SIDE CUTTING CARBIDE, 2 FLUTE BALL NOSE for RIB PROCESSING

EM662, EM833 SERIES EM967, EM886 SERIES

P P

MATERIAL NON-ALLOYED STEELS ALLOY STEELS ALLOY STEELS MATERIAL NON-ALLOYED STEELS

ALLOY STEELS HEAT RESISTANT HEAT RESISTANT HARDENED STEELS HARDENED STEELS ALLOY STEELS ALLOY STEELS HARDENED STEELS

CAST IRON STEELS STEELS CAST IRON HEAT RESISTANT STEELS

HARDNESS ~ HRc30 HRc30 ~ HRc38 HRc38 ~ HRc45 HRc45 ~ HRc55 HRc55 ~ HRc65 HARDNESS ~ HRc30 HRc30 ~ HRc45 HRc45 ~ HRc55

2

STRENGTH ~ 1000N/mm 2 1000 ~ 1200N/mm 2 1200 ~ 1400N/mm 2 1400 ~ 2000N/mm 2 2000N/mm ~ STRENGTH ~ 1000N/mm 2 1000 ~ 1500N/mm 2 1500 ~ 2000N/mm 2

DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED DIAMETER RPM FEED ap RPM FEED ap RPM FEED ap

R1/8 × 1/4 15600 91.3 12400 33.0 8400 22.4 3400 10.2 2400 7.5 R1/64 × 1/32 27000~35000 7.5~16.5 .0006~.0014 19500~24500 2.4~9.5 .0006~.0014 12500~14800 1.4~3.7 .0003~.0006

R5/32 × 5/16 11600 91.3 9200 33.0 6300 22.4 2400 9.4 1800 7.1 R.0234 × 3/64 18500~23500 7.5~23.6 .0022~.0039 13000~16500 3.7~11.8 .0022~.0039 8300~10500 2.0~3.9 .0004~.0009

R3/16 × 3/8 9200 91.3 7600 33.0 5100 22.4 2000 11.4 1300 7.5 R1/32 × 1/16 14000~18000 7.5~23.6 .0030~.0057 10200~12800 3.7~11.8 .0030~.0057 6400~8000 2.0~3.9 .0006~.0012

R1/4 × 1/2 8000 94.5 6000 31.5 4200 22.4 1680 10.2 1200 7.5 R.0391 × 5/64 12000~14500 7.5~23.6 .0035~.0071 8300~10500 3.7~11.8 .0035~.0071 5300~6600 2.0~3.9 .0007~.0014

R5/16 × 5/8 6000 94.5 4800 29.9 3300 20.1 1200 6.3 800 4.3 R3/64 × 3/32 9500~12000 7.5~23.6 .0044~.0093 6700~8500 3.7~11.8 .0044~.0093 4300~5300 2.0~3.9 .0009~.0018

R3/8 × 3/4 4800 85.0 3600 22.0 2400 14.1 1000 5.9 660 3.9 R1/16 × 1/8 8000~10000 7.5~23.6 .0053~.0106 5500~7000 3.7~11.8 .0053~.0106 3500~4400 2.0~3.9 .0011~.0022

1.5D 1.0D

(Depth of Cut per one pass)

0.3D 0.05D

RPM = rev./min. RPM = rev./min.

FEED = inch/min. FEED = inch/min.

CARBIDE, 2 FLUTE FINISH for RIB PROCESSING CARBIDE, 2 FLUTE TAPER - SIDE CUTTING

EM966, EM883 SERIES EM837 SERIES

P P

MATERIAL NON-ALLOYED STEELS ALLOY STEELS MATERIAL NON-ALLOYED STEELS ALLOY STEELS

ALLOY STEELS HEAT RESISTANT STEELS HARDENED STEELS ALLOY STEELS HEAT RESISTANT

CAST IRON STEELS

HARDNESS ~ HRc30 HRc30 ~ HRc45 HRc45 ~ HRc55 HARDNESS ~ HRc30 HRc30 ~ HRc45

STRENGTH ~ 1000N/mm 2 1000 ~ 1500N/mm 2 1500 ~ 2000N/mm 2 STRENGTH ~ 1000N/mm 2 1000 ~ 1500N/mm 2

DIAMETER RPM FEED ap RPM FEED ap RPM FEED ap DIAMETER RPM FEED RPM FEED

1/32 27000~35000 7.5~16.5 .0006~.0014 19500~24500 2.4~9.5 .0006~.0014 12500~14800 1.4~3.7 .0003~.0006 2.0 8400 6.7 6300 4.9

3/64 18500~23500 7.5~23.6 .0022~.0039 13000~16500 3.7~11.8 .0022~.0039 8300~10500 2.0~3.9 .0004~.0009 3.0 4410 4.7 3570 3.9

1/16 14000~18000 7.5~23.6 .0030~.0057 10200~12800 3.7~11.8 .0030~.0057 6400~8000 2.0~3.9 .0006~.0012 4.0 3570 5.5 2840 4.5

5/64 12000~14500 7.5~23.6 .0035~.0071 8300~10500 3.7~11.8 .0035~.0071 5300~6600 2.0~3.9 .0007~.0014 5.0 3050 7.1 2410 5.7

3/32 9500~12000 7.5~23.6 .0044~.0093 6700~8500 3.7~11.8 .0044~.0093 4300~5300 2.0~3.9 .0009~.0018 6.0 2630 8.3 2100 6.7

1/8 8000~10000 7.5~23.6 .0053~.0106 5500~7000 3.7~11.8 .0053~.0106 3500~4400 2.0~3.9 .0011~.0022 8.0 2000 9.8 1580 7.1

2.5D

(Depth of Cut per one pass)

0.05D

RPM = rev./min.

FEED = inch/min. RPM = rev./min.

FEED = inch/min.

930 • phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com phone:+1-800-765-8665, Technical Support : 888-868-5988, www.yg1usa.com • 931