Page 740 - CarrLaneCatalog_2019ed-c.pdf

P. 740

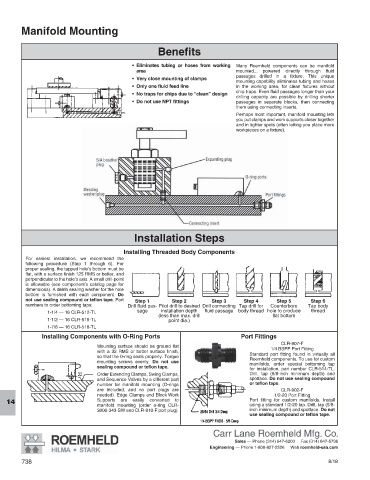

Manifold Mounting

Benefits

• Eliminates tubing or hoses from working Many Roemheld components can be manifold

area mounted... powered directly through fluid

passages drilled in a fixture. This unique

• Very close mounting of clamps

mounting capability eliminates tubing and hoses

• Only one fluid feed line in the working area, for clean fixtures without

chip traps. Even fluid passages longer than your

• No traps for chips due to “clean” design

drilling capacity are possible by drilling shorter

• Do not use NPT fittings passages in separate blocks, then connecting

them using connecting inserts.

Perhaps most important, manifold mounting lets

you put clamps and work supports closer together

and in tighter spots (often letting you place more

workpieces on a fixture).

Installation Steps

Installing Threaded Body Components

For easiest installation, we recommend the

following procedure (Step 1 through 6). For

proper sealing, the tapped hole’s bottom must be

flat, with a surface finish 125 RMS or better, and

perpendicular to the hole’s axis. A small drill-point

is allowable (see component’s catalog page for

dimensions). A delrin sealing washer for the hole

bottom is furnished with each component. Do

not use sealing compound or teflon tape. Part Step 1 Step 2 Step 3 Step 4 Step 5 Step 6

numbers to order bottoming taps: Drill fluid pas- Pilot drill to desired Drill connecting Tap drill for Counterbore Tap body

1-1/4 — 16 CLR-512-TL sage installation depth fluid passage body thread hole to produce thread

(less than max. drill flat bottom

1-1/2 — 16 CLR-515-TL point dia.)

1-7/8 — 16 CLR-518-TL

Installing Components with O-Ring Ports Port Fittings

CLR-807-F

Mounting surface should be ground flat 1/4 BSPP Port Fitting

with a 32 RMS or better surface finish,

so that the 0-ring seals properly. Torque Standard port fitting found in virtually all

Roemheld components. To use for custom

mounting screws evenly. Do not use manifolds, order special bottoming tap

sealing compound or teflon tape. for installation, part number CLR-514-TL.

Order Extending Clamps, Swing Clamps, Drill, tap (5/8-inch minimum depth) and

and Sequence Valves by a different part spotface. Do not use sealing compound

number for manifold mounting (O-rings or teflon tape.

are included, and no port plugs are CLR-902-F

needed). Edge Clamps and Block Work 1/2-20 Port Fitting

Supports are easily converted to Port fitting for custom manifolds. Install

manifold mounting (order o-ring CLR-

14 using a standard 1/2-20 tap. Drill, tap (5/8-

3000-343-SW and CLR-810-F port plug). inch minimum depth) and spotface. Do not

use sealing compound or teflon tape.

Carr Lane Roemheld Mfg. Co.

Sales — Phone (314) 647-6200 Fax (314) 647-5736

Engineering — Phone 1-800-827-2526 Web roemheld-usa.com

738 8/18