Page 340 - 3rd issue

P. 340

Telephone Wires & Cables

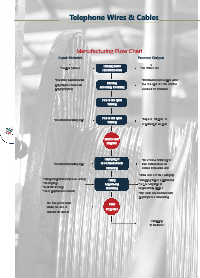

Manufacturing Flow Chart

Input Material Process Output

*Copper rod size Drawing M/CS *Cu. Wire 3 mm

Rod break down

*Insulation Material solid Drawing *Drawn Annealed copper wires

polyethylene foam skin Annealing, Insulating size 0.4 up to 0.9 mm and the

polythyethylene conductor is insulated

Pair or star quad

Twisting

*Identification Bilding tape Pair or star quad *5 quads. 10 pairs. no.

Twisting of pairs up to 25 pairs

Intermediate

Inspetion

*Identification Bilding tape Laying up of *No of sub-unit laid up to

sub-units and units form units and No. of

*Filling compound (Petroleum Jelley) units to form cable core

*Binding tape. Stranding

*ALU with PE tape *Cable core are filled with jelly,

*Black polyethelene sheath Filling *Wrapping tape is applied and

Lap serving *Lap serving tape is

NB. If requierd cable Sheathing longitudinally applied

will be aroured or *The cable are sheathed with

with double sheath Final polyethylene and marking

Inspection

Shapping

To Customer