Page 18 - CMA PROfiles Winter 2021

P. 18

That opportunity morphed into a traditional apprenticeship, in Colorado, but it has also completed projects in Florida, Texas,

and in 1983, Jordan became his mentor’s partner, an California, Utah, and Wyoming.

arrangement that lasted for several years. In 1992, he was “Custom cabinetry is our specialty, but we also do custom

inspired to open his own business. furniture and custom millwork, such as paneling systems, doors,

“My wife became the bookkeeper, and I was in the shop,” he and trim,” Jordan says. “The building community is fairly small,

remembers. “When you’re small like that, you wear all the hats. so there are contractors we’ve worked with for a long time who

I would go to a job site in the morning, do field measuring, meet know the kind of work that we do, and they bring that client to us.”

with clients, and what-not. I’d come back to the shop in the When Jordan first began his woodworking career, homes in

afternoon and work late into the night to keep up. We did that the area were more rustic, featuring distressed woodwork and

for about a year and realized that the volume of work coming other cabin-like design elements.

our way meant we needed to hire some employees. “In recent years, it’s shifted to more of what’s usually called

“Every year or two, the business seemed to grow one way or mountain contemporary — clean lines, but the wood has

another, leading to where we are today,” he says. “We own our textures or the finishes are unique and blend in with the other

own shop, and we have about 16 employees.” elements that are in the home,” he says.

“In the 90s, everything was hand-scraped — a real Craftsman

HIGH-END MEETS MODERN IN THE MOUNTAINS look,” Jordan recalls. “We still do that occasionally, but now

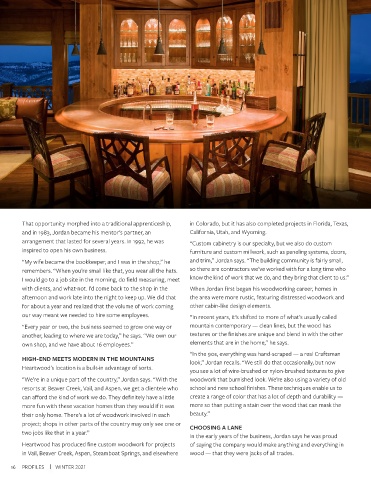

Heartwood’s location is a built-in advantage of sorts. you see a lot of wire-brushed or nylon-brushed textures to give

“We’re in a unique part of the country,” Jordan says. “With the woodwork that burnished look. We’re also using a variety of old

resorts at Beaver Creek, Vail, and Aspen, we get a clientele who school and new school finishes. These techniques enable us to

can afford the kind of work we do. They definitely have a little create a range of color that has a lot of depth and durability —

more fun with these vacation homes than they would if it was more so than putting a stain over the wood that can mask the

their only home. There’s a lot of woodwork involved in each beauty.”

project; shops in other parts of the country may only see one or CHOOSING A LANE

two jobs like that in a year.” In the early years of the business, Jordan says he was proud

Heartwood has produced fine custom woodwork for projects of saying the company would make anything and everything in

in Vail, Beaver Creek, Aspen, Steamboat Springs, and elsewhere wood — that they were jacks of all trades.

16 PROFILES WINTER 2021