Page 229 - Fanar

P. 229

Technical Information i

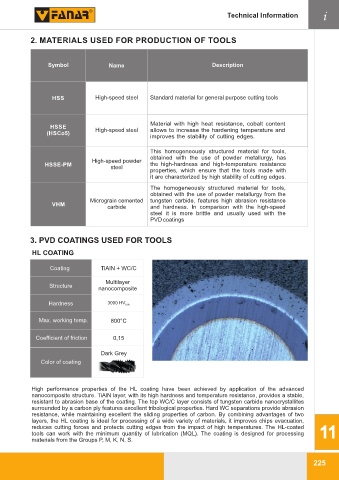

2. MATERIALS USED FOR PRODUCTION OF TOOLS

Symbol Name Description

HSS High-speed steel Standard material for general purpose cutting tools

Material with high heat resistance, cobalt content

HSSE High-speed steel allows to increase the hardening temperature and

(HSCo5)

improves the stability of cutting edges.

This homogeneously structured material for tools,

obtained with the use of powder metallurgy, has

High-speed powder

HSSE-PM the high-hardness and high-temperature resistance

steel

properties, which ensure that the tools made with

it are characterized by high stability of cutting edges.

The homogeneously structured material for tools,

obtained with the use of powder metallurgy from the

Micrograin cemented tungsten carbide, features high abrasion resistance

VHM

carbide and hardness. In comparison with the high-speed

steel it is more brittle and usually used with the

PVD coatings

3. PVD COATINGS USED FOR TOOLS

HL COATING

Coating TiAIN + WC/C

Multilayer

Structure

nanocomposite

Hardness 3000 HV 0,05

Max. working temp. 800°C

Coefficient of friction 0,15

Dark Grey

Color of coating

High performance properties of the HL coating have been achieved by application of the advanced

nanocomposite structure. TiAlN layer, with its high hardness and temperature resistance, provides a stable,

resistant to abrasion base of the coating. The top WC/C layer consists of tungsten carbide nanocrystallites

surrounded by a carbon ply features excellent tribological properties. Hard WC separations provide abrasion

resistance, while maintaining excellent the sliding properties of carbon. By combining advantages of two

layers, the HL coating is ideal for processing of a wide variety of materials, it improves chips evacuation,

reduces cutting forces and protects cutting edges from the impact of high temperatures. The HL-coated

tools can work with the minimum quantity of lubrication (MQL). The coating is designed for processing 11

materials from the Groups P, M, K, N, S.

225