Page 236 - Fanar

P. 236

i Technical Information

Straight Flutes with Spiral Point

Designed for through holes, with thread along the full length of the hole.

Used together with the chamfer B, it is recommended for materials giving a long chip. The spiral point moves

tightly squashed chips in the direction of feed, and prevents the grooves from clogging. Coolant reaches the

working zone freely. The length of threads, which can be made - up to ca 2xD.

Spiral flutes

Together with the chamfer C and E used for the blind holes.

It is recommended for materials giving a long chip. Spiral flutes provide good chip evacuation in the direction

from the hole toward the shank. Depending on the hole diameter, it is possible to make threads of up to 3xD.

Machine tap with spiral flutes should not be used for the through holes.

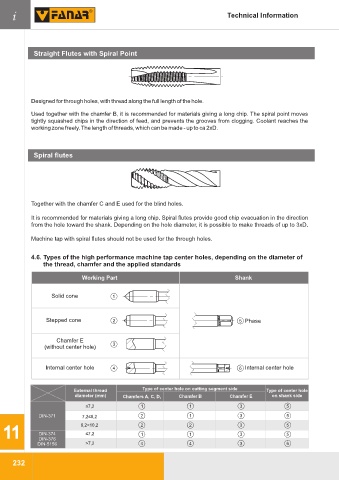

4.6. Types of the high performance machine tap center holes, depending on the diameter of

the thread, chamfer and the applied standards

Working Part Shank

Solid cone 1

Stepped cone 2 5 Phase

Chamfer E

(without center hole) 3

Kąty skręcenia spirali:

15°

30° Internal center hole 4 6 Internal center hole

40°

45°

Type of center hole on cutting segment side

External thread Type of center hole

diameter (mm) Chamfers A, C, D, Chamfer B Chamfer E on shank side

≤7,2 1 1 3 5

DIN-371 7,2≤8,2 2 1 3 5

8,2<10,2 2 2 3 5

11 DIN-374 ≤7,2 1 1 3 5

DIN-376

DIN-5156 >7,2 4 4 3 6

232