Page 241 - Fanar

P. 241

Technical Information i

Operation Recommendations

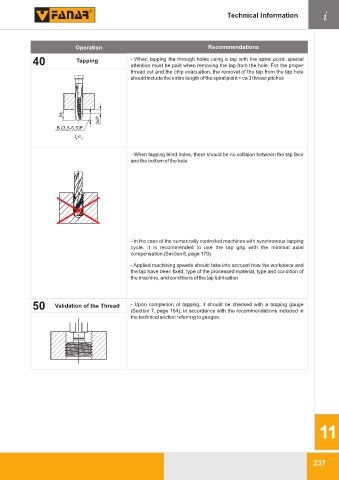

40 Tapping - When tapping the through holes using a tap with the spiral point, special

attention must be paid when removing the tap from the hole. For the proper

thread cut and the chip evacuation, the removal of the tap from the tap hole

should include the entire length of the spiral point + ca 3 thread pitches

3xP

B (3,5-5,5)P

l <l 2

w

- When tapping blind holes, there should be no collision between the tap face

and the bottom of the hole

- In the case of the numerically controlled machines with synchronous tapping

cycle, it is recommended to use the tap grip with the minimal axial

compensation (Section 8, page 179)

- Applied machining speeds should take into account how the workpiece and

the tap have been fixed, type of the processed material, type and condition of

the machine, and conditions of the tap lubrication

50 Validation of the Thread - Upon completion of tapping, it should be checked with a tapping gauge

(Section 7, page 164), in accordance with the recommendations included in

the technical section referring to gauges.

11

237