Page 240 - Fanar

P. 240

i Technical Information

4.10. Recommendations for Processing with Machine Taps

Tapping is usually one of the last operations in the process of machining a workpiece. An error occurring in the

process of tapping may result in additional costs associated not only with the damaged tap, but often with the

workpiece material, as well as with the machining processes preceding the tapping. In order to avoid such

problems, we encourage you to read and apply the below recommendations regarding the tapping process.

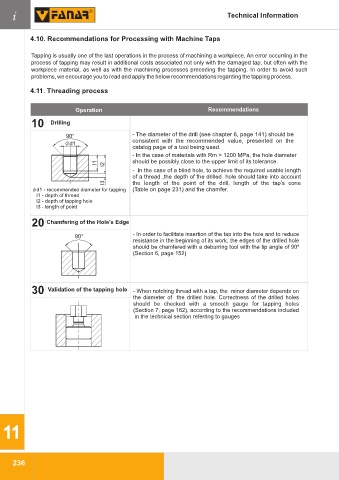

4.11. Threading process

Operation Recommendations

10 Drilling

90° - The diameter of the drill (see chapter 6, page 141) should be

consistent with the recommended value, presented on the

d1

catalog page of a tool being used.

- In the case of materials with Rm > 1200 MPa, the hole diameter

l1 l2 should be possibly close to the upper limit of its tolerance.

- In the case of a blind hole, to achieve the required usable length

of a thread ,the depth of the drilled hole should take into account

l3 the length of the point of the drill, length of the tap’s cone

d1 - recommended diameter for tapping (Table on page 231) and the chamfer.

l1 - depth of thread

l2 - depth of tapping hole

l3 - length of point

20 Chamfering of the Hole’s Edge

90° - In order to facilitate insertion of the tap into the hole and to reduce

resistance in the beginning of its work, the edges of the drilled hole

should be chamfered with a deburring tool with the tip angle of 90⁰

(Section 6, page 152)

30 Validation of the tapping hole - When notching thread with a tap, the minor diameter depends on

the diameter of the drilled hole. Correctness of the drilled holes

should be checked with a smooth gauge for tapping holes

(Section 7, page 162), according to the recommendations included

in the technical section referring to gauges

11

236