Page 95 - 100% Biker (January 2020)

P. 95

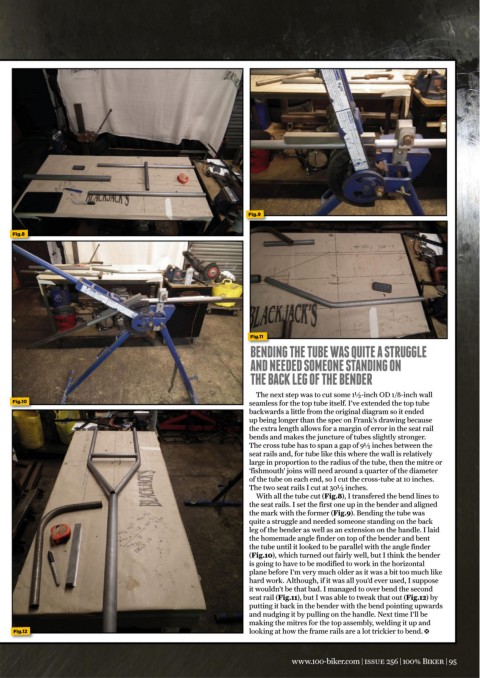

Fig.9

Fig.8

Fig.11

BENDING THE TUBE WAS QUITE A STRUGGLE

AND NEEDED SOMEONE STANDING ON

THE BACK LEG OF THE BENDER

The next step was to cut some 1½-inch OD 1/8-inch wall

Fig.10 seamless for the top tube itself. I’ve extended the top tube

backwards a little from the original diagram so it ended

up being longer than the spec on Frank’s drawing because

the extra length allows for a margin of error in the seat rail

bends and makes the juncture of tubes slightly stronger.

The cross tube has to span a gap of 9½ inches between the

seat rails and, for tube like this where the wall is relatively

large in proportion to the radius of the tube, then the mitre or

‘fishmouth’ joins will need around a quarter of the diameter

of the tube on each end, so I cut the cross-tube at 10 inches.

The two seat rails I cut at 30½ inches.

With all the tube cut (Fig.8), I transfered the bend lines to

the seat rails. I set the first one up in the bender and aligned

the mark with the former (Fig.9). Bending the tube was

quite a struggle and needed someone standing on the back

leg of the bender as well as an extension on the handle. I laid

the homemade angle finder on top of the bender and bent

the tube until it looked to be parallel with the angle finder

(Fig.10), which turned out fairly well, but I think the bender

is going to have to be modified to work in the horizontal

plane before I’m very much older as it was a bit too much like

hard work. Although, if it was all you’d ever used, I suppose

it wouldn’t be that bad. I managed to over bend the second

seat rail (Fig.11), but I was able to tweak that out (Fig.12) by

putting it back in the bender with the bend pointing upwards

and nudging it by pulling on the handle. Next time I’ll be

making the mitres for the top assembly, welding it up and

Fig.12 looking at how the frame rails are a lot trickier to bend. p

www.100-biker.com | issue 256 | 100% Biker | 95