Page 111 - How It Works - Book of Amazing Answers To Curious Questions, 12

P. 111

How do they

mal<e whisl<y?

Discover the complex,

multi-stage process involved in

making tfiis age-old alcoholic drin

Are there different types of he firstmain stage ofwhisky are disposed of and the wortis sent for

production is malting, a process

fermentation in a series of wooden

nuclrreac Tof soaking barley in water for containers called 'washbacks'. After two

days. This increases the moisture to three days in a washback, the wort

The most common design is the pressurised water reactor (PWR). PWRs content of the grains and causes generates a low-alcohol liquid, know as

I use pressurised water both as a moderator (the material that slows

down free neutrons, increasing the rate of fission reactions) and as a germination, which converts the starch the 'wash'.

coolant (the substance that transfers heat away from the reactor core to in the grains into fermentable sugars. Distillation follows, a complex process

the steam generator). Another common design, the advanced gas-cooled The grains are then separated from the of evaporation and condensing of the

reactor, uses graphite as a moderator and carbon dioxide as a coolant. The

chief advantage of this design is that it's possible to heat carbon dioxide to heated water and dried. wash in stills. This enriches the alcohol

higher temperatures than water (about 650°C vs 325°C). The greater heat Next, the dried malt is crushed into content of the wash and produces a

capacity greatly improves plant efficiency. grist and added to water, heated to 6ooc high-alcohol liquid that can then be

in a mashing process. This step creates a matured into drinkable whisky. Finally,

Advanced gas-cooled reactor (AGR) sugar solution (wort), which is then maturation is achieved by depositing the

Fuel element separated from the grains. The grains young whisky into oak casks.

Re-entrant gas Boiler

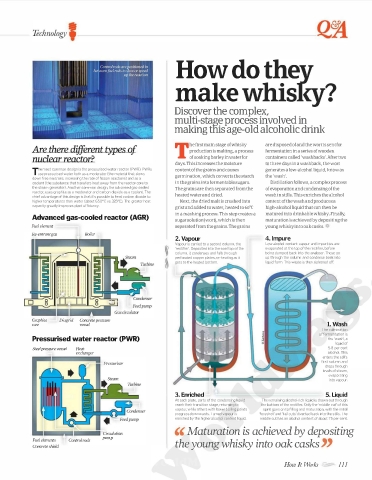

2. Vapour 4. 1mpure

Vapour is carried to a second column, the Low-alcohol content vapour and impurities are

'rectifier'. Deposited into the cool top of the evaporated at the top of the rectifier, before

column, it condenses and falls through being dumped back into the analyser. These go

perforated copper plates, re·heating as it up through the column and condense back into

gets to the heated bottom. liquid form. This waste is then siphoned off.

Graphite Diagrid Concrete pressure

core vessel l. Wash

The culmination

of fermentation is

Pressurised water reactor (PWR) the 'wash', a

liquid of

Steel pressure vessel Heat 5·8 per cent

exchanger alcohol. This

enters the still's

first column and

Pressuriser

drops through

levels of steam,

evaporating

into vapour.

3. Enriched 5. Liquid

At each plate, parts of the condensing liquid The remaining alcohol·rich liquid is drawn out through

reach their transition stage, returning to the bottom of the rectifier. Only the 'middle cut' of this

vapour, while others with lower boiling points spirit goes on to filling and maturation, with the initial

progress downwards. Turned vapour is 'foreshot' and 'tail cuts' diverted back into the stills. The

enriched by the higher alcohol content liquid. middle cut has an alcohol content of about 75 per cent.

'' Maturation is achieved by depositing

Circulation

pump

Fuel elements Control rods

Concrete shield the young whisky into oak casks''

WorldMags.net

WorldMags.net How It Works 111