Page 38 - BE Mech Curriculum and Syllabus - R2017 - REC

P. 38

Department of MECH | REC

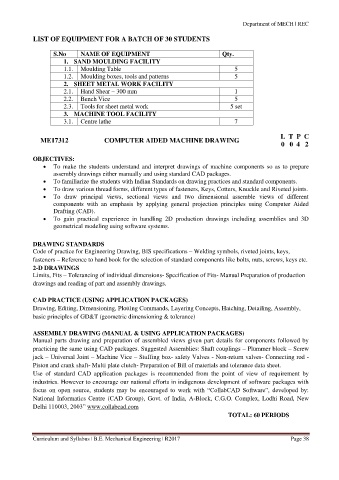

LIST OF EQUIPMENT FOR A BATCH OF 30 STUDENTS

S.No NAME OF EQUIPMENT Qty.

1. SAND MOULDING FACILITY

1.1. Moulding Table 5

1.2. Moulding boxes, tools and patterns 5

2. SHEET METAL WORK FACILITY

2.1. Hand Shear – 300 mm 1

2.2. Bench Vice 5

2.3. Tools for sheet metal work 5 set

3. MACHINE TOOL FACILITY

3.1. Centre lathe 7

L T P C

ME17312 COMPUTER AIDED MACHINE DRAWING

0 0 4 2

OBJECTIVES:

To make the students understand and interpret drawings of machine components so as to prepare

assembly drawings either manually and using standard CAD packages.

To familiarize the students with Indian Standards on drawing practices and standard components.

To draw various thread forms, different types of fasteners, Keys, Cotters, Knuckle and Riveted joints.

To draw principal views, sectional views and two dimensional assemble views of different

components with an emphasis by applying general projection principles using Computer Aided

Drafting (CAD).

To gain practical experience in handling 2D production drawings including assemblies and 3D

geometrical modeling using software systems.

DRAWING STANDARDS

Code of practice for Engineering Drawing, BIS specifications – Welding symbols, riveted joints, keys,

fasteners – Reference to hand book for the selection of standard components like bolts, nuts, screws, keys etc.

2-D DRAWINGS

Limits, Fits – Tolerancing of individual dimensions- Specification of Fits- Manual Preparation of production

drawings and reading of part and assembly drawings.

CAD PRACTICE (USING APPLICATION PACKAGES)

Drawing, Editing, Dimensioning, Plotting Commands, Layering Concepts, Hatching, Detailing, Assembly,

basic principles of GD&T (geometric dimensioning & tolerance)

ASSEMBLY DRAWING (MANUAL & USING APPLICATION PACKAGES)

Manual parts drawing and preparation of assembled views given part details for components followed by

practicing the same using CAD packages. Suggested Assemblies: Shaft couplings – Plummer block – Screw

jack – Universal Joint – Machine Vice – Stuffing box- safety Valves - Non-return valves- Connecting rod -

Piston and crank shaft- Multi plate clutch- Preparation of Bill of materials and tolerance data sheet.

Use of standard CAD application packages is recommended from the point of view of requirement by

industries. However to encourage our national efforts in indigenous development of software packages with

focus on open source, students may be encouraged to work with “CollabCAD Software”, developed by:

National Informatics Centre (CAD Group), Govt. of India, A-Block, C.G.O. Complex, Lodhi Road, New

Delhi 110003, 2003” www.collabcad.com

TOTAL: 60 PERIODS

Curriculum and Syllabus | B.E. Mechanical Engineering | R2017 Page 38