Page 52 - BE Mech Curriculum and Syllabus - R2017 - REC

P. 52

Department of MECH | REC

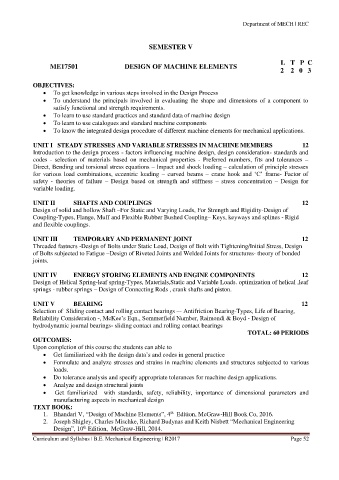

SEMESTER V

L T P C

ME17501 DESIGN OF MACHINE ELEMENTS

2 2 0 3

OBJECTIVES:

To get knowledge in various steps involved in the Design Process

To understand the principals involved in evaluating the shape and dimensions of a component to

satisfy functional and strength requirements.

To learn to use standard practices and standard data of machine design

To learn to use catalogues and standard machine components

To know the integrated design procedure of different machine elements for mechanical applications.

UNIT I STEADY STRESSES AND VARIABLE STRESSES IN MACHINE MEMBERS 12

Introduction to the design process - factors influencing machine design, design consideration- standards and

codes - selection of materials based on mechanical properties - Preferred numbers, fits and tolerances –

Direct, Bending and torsional stress equations – Impact and shock loading – calculation of principle stresses

for various load combinations, eccentric loading – curved beams – crane hook and ‘C’ frame- Factor of

safety - theories of failure – Design based on strength and stiffness – stress concentration – Design for

variable loading.

UNIT II SHAFTS AND COUPLINGS 12

Design of solid and hollow Shaft –For Static and Varying Loads, For Strength and Rigidity-Design of

Coupling-Types, Flange, Muff and Flexible Rubber Bushed Coupling– Keys, keyways and splines - Rigid

and flexible couplings.

UNIT III TEMPORARY AND PERMANENT JOINT 12

Threaded fastners -Design of Bolts under Static Load, Design of Bolt with Tightening/Initial Stress, Design

of Bolts subjected to Fatigue –Design of Riveted Joints and Welded Joints for structures- theory of bonded

joints.

UNIT IV ENERGY STORING ELEMENTS AND ENGINE COMPONENTS 12

Design of Helical Spring-leaf spring-Types, Materials,Static and Variable Loads. optimization of helical ,leaf

springs - rubber springs – Design of Connecting Rods , crank shafts and piston.

UNIT V BEARING 12

Selection of Sliding contact and rolling contact bearings –- Antifriction Bearing-Types, Life of Bearing,

Reliability Consideration -, McKee’s Eqn., Sommerfield Number, Raimondi & Boyd - Design of

hydrodynamic journal bearings- sliding contact and rolling contact bearings

TOTAL: 60 PERIODS

OUTCOMES:

Upon completion of this course the students can able to

Get familiarized with the design data’s and codes in general practice

Formulate and analyze stresses and strains in machine elements and structures subjected to various

loads.

Do tolerance analysis and specify appropriate tolerances for machine design applications.

Analyze and design structural joints

Get familiarized with standards, safety, reliability, importance of dimensional parameters and

manufacturing aspects in mechanical design

TEXT BOOK:

1. Bhandari V, “Design of Machine Elements”, 4 Edition, McGraw-Hill Book Co, 2016.

th

2. Joseph Shigley, Charles Mischke, Richard Budynas and Keith Nisbett “Mechanical Engineering

th

Design”, 10 Edition, McGraw-Hill, 2014.

Curriculum and Syllabus | B.E. Mechanical Engineering | R2017 Page 52