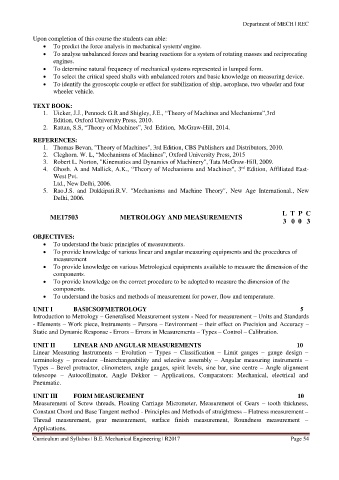

Page 54 - BE Mech Curriculum and Syllabus - R2017 - REC

P. 54

Department of MECH | REC

Upon completion of this course the students can able:

To predict the force analysis in mechanical system/ engine.

To analyse unbalanced forces and bearing reactions for a system of rotating masses and reciprocating

engines.

To determine natural frequency of mechanical systems represented in lumped form.

To select the critical speed shafts with unbalanced rotors and basic knowledge on measuring device.

To identify the gyroscopic couple or effect for stabilization of ship, aeroplane, two wheeler and four

wheeler vehicle.

TEXT BOOK:

1. Uicker, J.J., Pennock G.R and Shigley, J.E., “Theory of Machines and Mechanisms”,3rd

Edition, Oxford University Press, 2010.

2. Rattan, S.S, “Theory of Machines”, 3rd Edition, McGraw-Hill, 2014.

REFERENCES:

1. Thomas Bevan, "Theory of Machines", 3rd Edition, CBS Publishers and Distributors, 2010.

2. Cleghorn. W. L, “Mechanisms of Machines”, Oxford University Press, 2015

3. Robert L. Norton, "Kinematics and Dynamics of Machinery", Tata McGraw-Hill, 2009.

4. Ghosh. A and Mallick, A.K., “Theory of Mechanisms and Machines", 3 Edition, Affiliated East-

rd

West Pvt.

Ltd., New Delhi, 2006.

5. Rao.J.S. and Dukkipati.R.V. "Mechanisms and Machine Theory", New Age International., New

Delhi, 2006.

L T P C

ME17503 METROLOGY AND MEASUREMENTS

3 0 0 3

OBJECTIVES:

To understand the basic principles of measurements.

To provide knowledge of various linear and angular measuring equipments and the procedures of

measurement

To provide knowledge on various Metrological equipments available to measure the dimension of the

components.

To provide knowledge on the correct procedure to be adopted to measure the dimension of the

components.

To understand the basics and methods of measurement for power, flow and temperature.

UNIT I BASICSOFMETROLOGY 5

Introduction to Metrology – Generalised Measurement system - Need for measurement – Units and Standards

- Elements – Work piece, Instruments – Persons – Environment – their effect on Precision and Accuracy –

Static and Dynamic Response - Errors – Errors in Measurements – Types – Control – Calibration.

UNIT II LINEAR AND ANGULAR MEASUREMENTS 10

Linear Measuring Instruments – Evolution – Types – Classification – Limit gauges – gauge design –

terminology – procedure –Interchangeability and selective assembly – Angular measuring instruments –

Types – Bevel protractor, clinometers, angle gauges, spirit levels, sine bar, sine centre – Angle alignment

telescope – Autocollimator, Angle Dekkor – Applications, Comparators: Mechanical, electrical and

Pneumatic.

UNIT III FORM MEASUREMENT 10

Measurement of Screw threads, Floating Carriage Micrometer, Measurement of Gears – tooth thickness,

Constant Chord and Base Tangent method - Principles and Methods of straightness – Flatness measurement –

Thread measurement, gear measurement, surface finish measurement, Roundness measurement –

Applications.

Curriculum and Syllabus | B.E. Mechanical Engineering | R2017 Page 54