Page 87 - MBA curriculum and syllabus R2017 - REC

P. 87

Department of MBA, REC

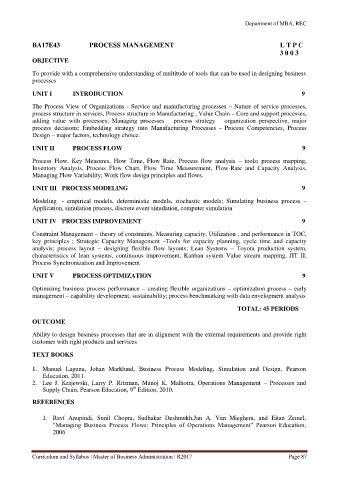

BA17E43 PROCESS MANAGEMENT L T P C

3 0 0 3

OBJECTIVE

To provide with a comprehensive understanding of multitude of tools that can be used in designing business

processes

UNIT I INTRODUCTION 9

The Process View of Organizations - Service and manufacturing processes – Nature of service processes,

process structure in services, Process structure in Manufacturing , Value Chain – Core and support processes,

adding value with processes; Managing processes – process strategy – organization perspective, major

process decisions; Embedding strategy into Manufacturing Processes - Process Competencies, Process

Design – major factors, technology choice.

UNIT II PROCESS FLOW 9

Process Flow, Key Measures, Flow Time, Flow Rate, Process flow analysis – tools; process mapping,

Inventory Analysis, Process Flow Chart, Flow Time Measurement, Flow-Rate and Capacity Analysis,

Managing Flow Variability; Work flow design principles and flows.

UNIT III PROCESS MODELING 9

Modeling - empirical models, deterministic models, stochastic models; Simulating business process –

Application, simulation process, discrete event simulation, computer simulation

UNIT IV PROCESS IMPROVEMENT 9

Constraint Management – theory of constraints, Measuring capacity, Utilization , and performance in TOC,

key principles ; Strategic Capacity Management –Tools for capacity planning, cycle time and capacity

analysis; process layout – designing flexible flow layouts; Lean Systems – Toyota production system,

characteristics of lean systems, continuous improvement, Kanban system Value stream mapping, JIT II;

Process Synchronization and Improvement

UNIT V PROCESS OPTIMIZATION 9

Optimizing business process performance – creating flexible organizations – optimization process – early

management – capability development, sustainability; process benchmarking with data envelopment analysis

TOTAL: 45 PERIODS

OUTCOME

Ability to design business processes that are in alignment with the external requirements and provide right

customer with right products and services

TEXT BOOKS

1. Manuel Laguna, Johan Marklund, Business Process Modeling, Simulation and Design, Pearson

Education, 2011.

2. Lee J. Krajewski, Larry P. Ritzman, Manoj K. Malhotra, Operations Management – Processes and

th

Supply Chain, Pearson Education, 9 Edition, 2010.

REFERENCES

1. Raví Anupindi, Sunil Chopra, Sudhakar Deshmukh,Jan A. Van Mieghem, and Eitan Zemel,

“Managing Business Process Flows: Principles of Operations Management” Pearson Education,

2006

Curriculum and Syllabus | Master of Business Administration | R2017 Page 87