Page 148 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 148

The City & Guilds Textbook: Plumbing Book 1

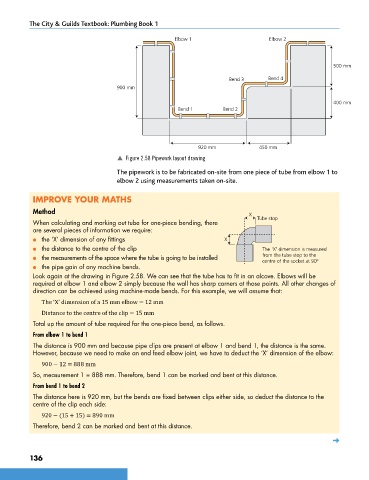

Elbow 1 Elbow 2

500 mm

Bend 3 Bend 4

900 mm

400 mm

Bend 1 Bend 2

920 mm 450 mm

p Figure 2.58 Pipework layout drawing

The pipework is to be fabricated on-site from one piece of tube from elbow 1 to

elbow 2 using measurements taken on-site.

IMPROVE YOUR MATHS

Method X

When calculating and marking out tube for one-piece bending, there Tube stop

are several pieces of information we require:

● the ‘X’ dimension of any fittings X

● the distance to the centre of the clip The 'X' dimension is measured

● the measurements of the space where the tube is going to be installed from the tube stop to the

centre of the socket at 90º

● the pipe gain of any machine bends.

Look again at the drawing in Figure 2.58. We can see that the tube has to fit in an alcove. Elbows will be

required at elbow 1 and elbow 2 simply because the wall has sharp corners at those points. All other changes of

direction can be achieved using machine-made bends. For this example, we will assume that:

The ‘X’ dimension of a 15 mm elbow = 12 mm

Distance to the centre of the clip = 15 mm

Total up the amount of tube required for the one-piece bend, as follows.

From elbow 1 to bend 1

The distance is 900 mm and because pipe clips are present at elbow 1 and bend 1, the distance is the same.

However, because we need to make an end feed elbow joint, we have to deduct the ‘X’ dimension of the elbow:

900 − 12 = 888 mm

So, measurement 1 = 888 mm. Therefore, bend 1 can be marked and bent at this distance.

From bend 1 to bend 2

The distance here is 920 mm, but the bends are fixed between clips either side, so deduct the distance to the

centre of the clip each side:

920 − (15 + 15) = 890 mm

Therefore, bend 2 can be marked and bent at this distance.

➜

136

9781510416482.indb 136 29/03/19 8:54 PM