Page 347 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 347

Chapter 5 Cold water systems

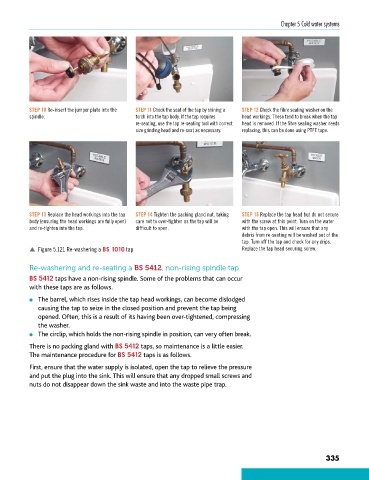

STEP 10 Re-insert the jumper plate into the STEP 11 Check the seat of the tap by shining a STEP 12 Check the fibre sealing washer on the

spindle. torch into the tap body. If the tap requires head workings. These tend to break when the tap

re-seating, use the tap re-seating tool with correct head is removed. If the fibre sealing washer needs

size grinding head and re-seat as necessary. replacing, this can be done using PTFE tape.

STEP 13 Replace the head workings into the tap STEP 14 Tighten the packing gland nut, taking STEP 15 Replace the tap head but do not secure

body (ensuring the head workings are fully open) care not to over-tighten as the tap will be with the screw at this point. Turn on the water

and re-tighten into the tap. difficult to open. with the tap open. This will ensure that any

debris from re-seating will be washed out of the

tap. Turn off the tap and check for any drips.

p Figure 5.121 Re-washering a BS 1010 tap Replace the tap head securing screw.

Re-washering and re-seating a BS 5412, non-rising spindle tap

BS 5412 taps have a non-rising spindle. Some of the problems that can occur

with these taps are as follows.

● The barrel, which rises inside the tap head workings, can become dislodged

causing the tap to seize in the closed position and prevent the tap being

opened. Often, this is a result of its having been over-tightened, compressing

the washer.

● The circlip, which holds the non-rising spindle in position, can very often break.

There is no packing gland with BS 5412 taps, so maintenance is a little easier.

The maintenance procedure for BS 5412 taps is as follows.

First, ensure that the water supply is isolated, open the tap to relieve the pressure

and put the plug into the sink. This will ensure that any dropped small screws and

nuts do not disappear down the sink waste and into the waste pipe trap.

335

9781510416482.indb 335 29/03/19 9:00 PM