Page 609 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 609

Chapter 9 Sanitation systems

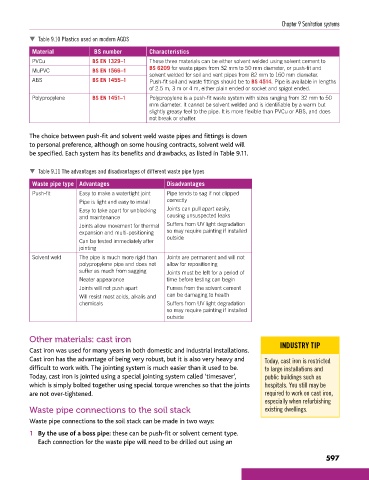

Table 9.10 Plastics used on modern AGDS

Material BS number Characteristics

PVCu BS EN 1329–1 These three materials can be either solvent welded using solvent cement to

MuPVC BS EN 1566–1 BS 6209 for waste pipes from 32 mm to 50 mm diameter, or push-fit and

solvent welded for soil and vent pipes from 82 mm to 160 mm diameter.

ABS BS EN 1455–1 Push-fit soil and waste fittings should be to BS 4514. Pipe is available in lengths

of 2.5 m, 3 m or 4 m, either plain ended or socket and spigot ended.

Polypropylene BS EN 1451–1 Polypropylene is a push-fit waste system with sizes ranging from 32 mm to 50

mm diameter. It cannot be solvent welded and is identifiable by a warm but

slightly greasy feel to the pipe. It is more flexible than PVCu or ABS, and does

not break or shatter.

The choice between push-fit and solvent weld waste pipes and fittings is down

to personal preference, although on some housing contracts, solvent weld will

be specified. Each system has its benefits and drawbacks, as listed in Table 9.11.

Table 9.11 The advantages and disadvantages of different waste pipe types

Waste pipe type Advantages Disadvantages

Push-fit Easy to make a watertight joint Pipe tends to sag if not clipped

Pipe is light and easy to install correctly

Easy to take apart for unblocking Joints can pull apart easily,

and maintenance causing unsuspected leaks

Joints allow movement for thermal Suffers from UV light degradation

expansion and multi-positioning so may require painting if installed

Can be tested immediately after outside

jointing

Solvent weld The pipe is much more rigid than Joints are permanent and will not

polypropylene pipe and does not allow for repositioning

suffer as much from sagging Joints must be left for a period of

Neater appearance time before testing can begin

Joints will not push apart Fumes from the solvent cement

Will resist most acids, alkalis and can be damaging to health

chemicals Suffers from UV light degradation

so may require painting if installed

outside

Other materials: cast iron

Cast iron was used for many years in both domestic and industrial installations. INDUSTRY TIP

Cast iron has the advantage of being very robust, but it is also very heavy and Today, cast iron is restricted

difficult to work with. The jointing system is much easier than it used to be. to large installations and

Today, cast iron is jointed using a special jointing system called ‘timesaver’, public buildings such as

which is simply bolted together using special torque wrenches so that the joints hospitals. You still may be

are not over-tightened. required to work on cast iron,

especially when refurbishing

Waste pipe connections to the soil stack existing dwellings.

Waste pipe connections to the soil stack can be made in two ways:

1 By the use of a boss pipe: these can be push-fit or solvent cement type.

Each connection for the waste pipe will need to be drilled out using an

597

9781510416482.indb 597 29/03/19 9:07 PM