Page 690 - The City and Guilds Textbook: Plumbing Book 1 for the Level 3 Apprenticeship (9189), Level 2 Technical Certificate (8202) and Level 2 Diploma (6035)

P. 690

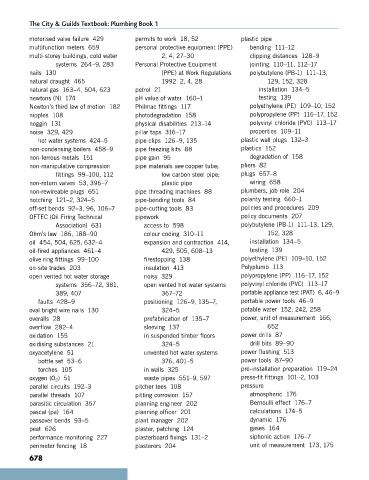

The City & Guilds Textbook: Plumbing Book 1

motorised valve failure 429 permits to work 18, 52 plastic pipe

multifunction meters 659 personal protective equipment (PPE) bending 111–12

multi-storey buildings, cold water 2, 4, 27–30 clipping distances 128–9

systems 264–9, 283 Personal Protective Equipment jointing 110–11, 112–17

nails 130 (PPE) at Work Regulations polybutylene (PB-1) 111–13,

natural draught 465 1992 2, 4, 28 129, 152, 328

natural gas 163–4, 504, 623 petrol 21 installation 134–5

newtons (N) 174 pH value of water 160–1 testing 139

Newton’s third law of motion 182 Philmac fittings 117 polyethylene (PE) 109–10, 152

nipples 108 photodegradation 158 polypropylene (PP) 116–17, 152

noggin 131 physical disabilities 213–14 polyvinyl chloride (PVC) 113–17

noise 329, 429 pillar taps 316–17 properties 109–11

hot water systems 424–5 pipe clips 126–9, 135 plastic wall plugs 132–3

non-condensing boilers 458–9 pipe freezing kits 88 plastics 152

non-ferrous metals 151 pipe gain 95 degradation of 158

non-manipulative compression pipe materials see copper tube; pliers 82

fittings 99–100, 112 low carbon steel pipe; plugs 657–8

non-return valves 53, 396–7 plastic pipe wiring 658

non-rewireable plugs 651 pipe threading machines 88 plumbers, job role 204

notching 121–2, 324–5 pipe-bending tools 84 polarity testing 660–1

off-set bends 92–3, 96, 106–7 pipe-cutting tools 83 policies and procedures 209

OFTEC (Oil Firing Technical pipework policy documents 207

Association) 631 access to 598 polybutylene (PB-1) 111–13, 129,

Ohm’s law 186, 188–90 colour coding 310–11 152, 328

oil 454, 504, 625, 632–4 expansion and contraction 414, installation 134–5

oil-fired appliances 461–4 429, 505, 608–13 testing 139

olive ring fittings 99–100 firestopping 138 polyethylene (PE) 109–10, 152

on-site trades 203 insulation 413 Polyplumb 113

open vented hot water storage noisy 329 polypropylene (PP) 116–17, 152

systems 356–72, 381, open vented hot water systems polyvinyl chloride (PVC) 113–17

389, 407 367–72 portable appliance test (PAT) 6, 46–9

faults 428–9 positioning 126–9, 135–7, portable power tools 46–9

oval bright wire nails 130 324–5 potable water 152, 242, 258

overalls 28 prefabrication of 135–7 power, unit of measurement 166,

overflow 282–4 sleeving 137 652

oxidation 155 in suspended timber floors power drills 87

oxidising substances 21 324–5 drill bits 89–90

oxyacetylene 51 unvented hot water systems power flushing 513

bottle set 53–6 376, 401–5 power tools 87–90

torches 105 in walls 325 pre-installation preparation 119–24

oxygen (O 2 ) 51 waste pipes 551–9, 597 press-fit fittings 101–2, 103

parallel circuits 192–3 pitcher tees 108 pressure

parallel threads 107 pitting corrosion 157 atmospheric 176

parasitic circulation 357 planning engineer 202 Bernoulli effect 176–7

pascal (pa) 164 planning officer 201 calculations 174–5

passover bends 93–5 plant manager 202 dynamic 176

peat 626 plaster, patching 124 gases 164

performance monitoring 227 plasterboard fixings 131–2 siphonic action 176–7

perimeter fencing 18 plasterers 204 unit of measurement 173, 175

678

9781510416482.indb 678 29/03/19 9:09 PM