Page 20 - Template Tesis UTM v2.0

P. 20

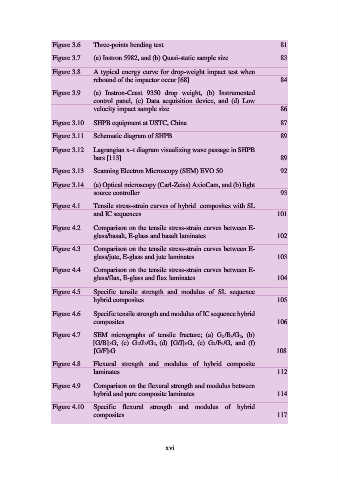

Figure 3.6 Three-points bending test 81

Figure 3.7 (a) Instron 5982, and (b) Quasi-static sample size 83

Figure 3.8 A typical energy curve for drop-weight impact test when

rebound of the impactor occur [68] 84

Figure 3.9 (a) Instron-Ceast 9350 drop weight, (b) Instrumented

control panel, (c) Data acquisition device, and (d) Low

velocity impact sample size 86

Figure 3.10 SHPB equipment at USTC, China 87

Figure 3.11 Schematic diagram of SHPB 89

Figure 3.12 Lagrangian x–t diagram visualizing wave passage in SHPB

bars [113] 89

Figure 3.13 Scanning Electron Microscopy (SEM) EVO 50 92

Figure 3.14 (a) Optical microscopy (Carl-Zeiss) AxioCam, and (b) light

source controller 93

Figure 4.1 Tensile stress-strain curves of hybrid composites with SL

and IC sequences 101

Figure 4.2 Comparison on the tensile stress-strain curves between E-

glass/basalt, E-glass and basalt laminates 102

Figure 4.3 Comparison on the tensile stress-strain curves between E-

glass/jute, E-glass and jute laminates 103

Figure 4.4 Comparison on the tensile stress-strain curves between E-

glass/flax, E-glass and flax laminates 104

Figure 4.5 Specific tensile strength and modulus of SL sequence

hybrid composites 105

Figure 4.6 Specific tensile strength and modulus of IC sequence hybrid

composites 106

Figure 4.7 SEM micrographs of tensile fracture; (a) G2/B3/G2, (b)

[G/B]3G, (c) G2/J3/G2, (d) [G/J]3G, (e) G2/F3/G, and (f)

[G/F]3G 108

Figure 4.8 Flexural strength and modulus of hybrid composite

laminates 112

Figure 4.9 Comparison on the flexural strength and modulus between

hybrid and pure composite laminates 114

Figure 4.10 Specific flexural strength and modulus of hybrid

composites 117

xvi