Page 66 - Template Tesis UTM v2.0

P. 66

Vacuum infusion process (VIP) can be considered as a low-cost process. In

this process, the pressure gradient is created by vacuum on the outlet ports and the inlet

ports or resin injection tanks are at ambient pressure, as opposed to RTM where the

resin injection tank is pressurised. The use of VIP is advantageous as it could produce

large products at small volumes due to the absence of large force on the mould in

comparison to RTM which requires stiffness and strength of the tooling design and

production [69].

2.10 Previous Literature of Using VIP in the Fabrication of Composite

Materials

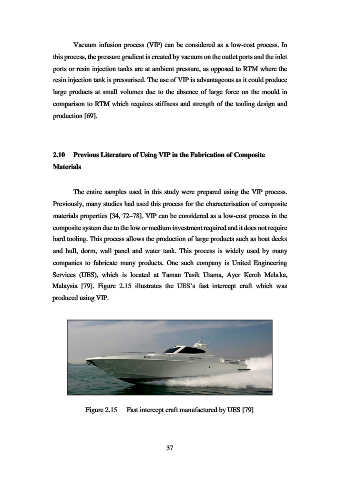

The entire samples used in this study were prepared using the VIP process.

Previously, many studies had used this process for the characterisation of composite

materials properties [34, 72–78]. VIP can be considered as a low-cost process in the

composite system due to the low or medium investment required and it does not require

hard tooling. This process allows the production of large products such as boat decks

and hull, dorm, wall panel and water tank. This process is widely used by many

companies to fabricate many products. One such company is United Engineering

Services (UES), which is located at Taman Tasik Utama, Ayer Keroh Melaka,

Malaysia [79]. Figure 2.15 illustrates the UES’s fast intercept craft which was

produced using VIP.

Figure 2.15 Fast intercept craft manufactured by UES [79]

37