Page 84 - 2010-2022 hose manufactureing ability and guide

P. 84

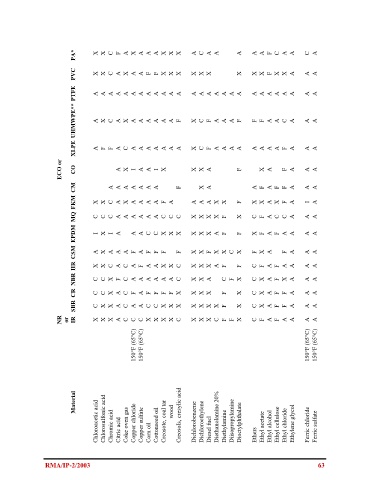

PA* X X C F A X A A A X X X A C A A A A A F C A A C A

PVC X X C A X A A F F X X X X X X X X X F X X A A A

A A A A A A A A A A A A A A A A A A A A A A A A A A A

XLPE UHMWPE** PTFE A X C A X A A A A A A F X C F A A A F F F A A C A A A

A F F A C A A A A A A A X C F A A A A A A A A F A A A

ECO or CO A X I A A I X X X A F X A F A A A

EPDM MQ FKM CM

A A A A A A A F X A A F A F F A A A

X X C A X A A A A F A A A A X X F X X A X F A I A

C C C A A A A A A C C C X X X X F X C F A C C A A A

I X I A A A C C X X X X X X A F F X F A F A A A A

NBR IIR CSM X X C A C A F A A X X C X X X A F F C F A F A A A A

A X A A A F A F F F F X X F X X C X F X A F A A A

C C X F C A A A A A A C X X A C F X C X A F X A A A

CR C C X A C F A F F F F X X X X F X C X A F F A A A

SBR C X X A C A A C C X X X X X X X F X C X A F F A A A

NR IR X X X A C C C X X X X C X X X C F F X C F A F A A A A

or

150°F (65°C) 150°F (65°C) 150°F (65°C) 150°F (65°C)

Material

Chloroacetic acid Chlorosulfonic acid Chromic acid Citric acid Coke oven gas Copper chloride Copper sulfate Cottonseed oil Creosote, coal tar wood CreosoIs, cresylic acid Dichlorobenzene Dichloroethylene Diesel fuel Diethanolamine 20% Diethylamine Diisopropylamine Dioctylphthalate Ethyl acetate Ethyl alcohol Ethyl cellulose Ethyl chloride Ethylene glycol Ferric chloride F

Corn oil Ethers

RMA/IP-2/2003 63