Page 89 - 2010-2022 hose manufactureing ability and guide

P. 89

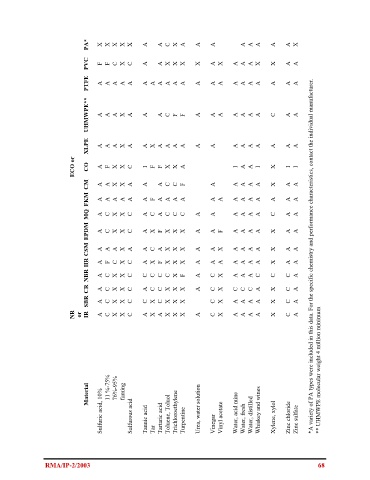

PA* X X X X X A A C X A A A A A A A A X

PVC F F C X C A A X X X X A X A A A X X A A

PTFE A A A A A A A A A A A A A A A A A A A A A

UHMWPE** A A A X A A A C F F A A A A A A A C A A

XLPE A A A X A A X A A A A A A A A A A A A A

ECO or C

CO A F X X I F F X X A I A A I X I I

CM

A A X X A A A C C F A A A A A X A A

MQ FKM

A A A A A A F A A A A A A A A A A A A A

A C X X C A C A C C C A A A A A A C A A

SBR CR NBR IIR CSM EPDM

A C X X C A X F X X X A A F A A A A X A A

A A A X A A C A X X X A A X A A A A X A A *A variety of PA types were included in this data. For the specific chemistry and performance characteristics, contact the individual manufacturer.

A F C X C A X F X X X A A A A A A A X A A

A C X X C C C C C X F A C X A A A C C C A

A C X X C A C C X X X A C X C C C A X C A

A C X X C C X C X X X C X A A A A X C A

NR C C C C

or IR A X X A X A X X X A X A A A A X A

** UHMWPE molecular weight 4 million minimum

Material

Sulfuric acid, 10% 11 %-75% 76%-95% fuming Sulfurous acid Tannic acid Tar Tartaric acid Toluene, Toluol Trichloroethylene Turpentine Urea, water solution Vinegar Vinyl acetate Water, acid mine Water, fresh Water, distilled Whiskey and wines Xylene, xylol Zinc chloride Zinc sulfate

RMA/IP-2/2003 68