Page 88 - 2010-2022 hose manufactureing ability and guide

P. 88

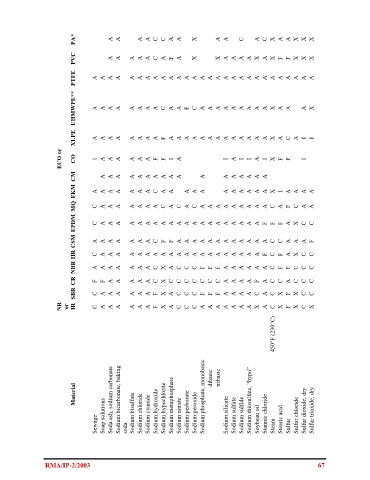

PA* A A A A C C A A X A A C A C X A A X X X

PVC A A A A A C A F A X X A A A A X A X F F X X X

PTFE A A A A A A A A A A A A A A A A A A A A A A A A A A A A

UHMWPE** A A A A A A A A C A A F C A A A A A A A A A X A A A X

XLPE A A A A A A A A A A A A A A A A A A A A A X A C A

F I I

ECO or

CO l A A A A A A F F I A I A I I A I X F F I

CM A A A A A A A A A A A A A A A A A

MQ FKM

A A A A A A A C A A A A A A A A A A A X I A A A A

C A A A A A A A C A C A C A A A A A A A A A C A F C A A

SBR CR NBR IIR CSM EPDM

C A A A A A A A A A A A A A A A A A A A A F F F A X C C

A A A A A A A C F F A A A A A A A A A A A A C C A A A F

C A A A A A A A A A A A A A A A A A A A A F C F A X C C

A A A A A A A C X A C C C F F F A A A A A A C F F C C C

F F A A A A A C X C C C C C C C A A A A F A C C A C C C

C A A A A A A F X A C C C F F F A A A A C A C X F X C C

NR IR

or C A A A A A A F X A C C C A A A A A A A X A C X F X C X

450°F (230°C)

Material Soda ash, sodium carbonate Sodium bicarbonate, baking Sodium hypochlorite Sodium metaphosphate Sodium phosphate, monobasic dibasic tribasic Sodium thiosulfate, “hypo”

Sewage Soap solutions soda Sodium bisulfate Sodium chloride Sodium cyanide Sodium hydroxide Sodium nitrate Sodium perborate Sodium peroxide Sodium silicate Sodium sulfate Sodium sulfide Soybean oil Stannic chloride Steam Stearic acid Sulfur Sulfur chloride Sulfur dioxide, dry Sulfur trioxide, dry

RMA/IP-2/2003 67