Page 17 - REPOWER REFERENCE GUIDE (2020)

P. 17

Important Information

Although the occurrence is rare, on a very calm day, swimmers and passengers in an open area of a stationary boat that

contains or is near an operating engine may be exposed to a hazardous level of carbon monoxide.

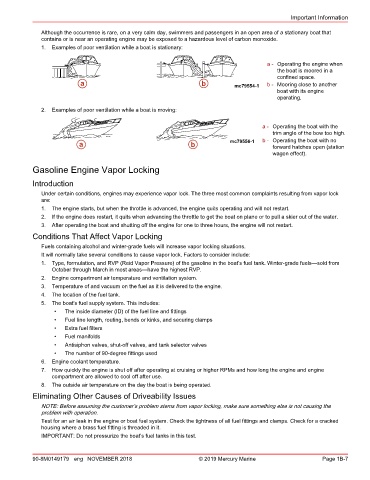

1. Examples of poor ventilation while a boat is stationary:

a - Operating the engine when

the boat is moored in a

confined space.

a b mc79554-1 b - Mooring close to another

boat with its engine

operating.

2. Examples of poor ventilation while a boat is moving:

a - Operating the boat with the

trim angle of the bow too high.

a b mc79556-1 b - Operating the boat with no

forward hatches open (station

wagon effect).

Gasoline Engine Vapor Locking

Introduction

Under certain conditions, engines may experience vapor lock. The three most common complaints resulting from vapor lock

are:

1. The engine starts, but when the throttle is advanced, the engine quits operating and will not restart.

2. If the engine does restart, it quits when advancing the throttle to get the boat on plane or to pull a skier out of the water.

3. After operating the boat and shutting off the engine for one to three hours, the engine will not restart.

Conditions That Affect Vapor Locking

Fuels containing alcohol and winter‑grade fuels will increase vapor locking situations.

It will normally take several conditions to cause vapor lock. Factors to consider include:

1. Type, formulation, and RVP (Reid Vapor Pressure) of the gasoline in the boat’s fuel tank. Winter‑grade fuels—sold from

October through March in most areas—have the highest RVP.

2. Engine compartment air temperature and ventilation system.

3. Temperature of and vacuum on the fuel as it is delivered to the engine.

4. The location of the fuel tank.

5. The boat’s fuel supply system. This includes:

• The inside diameter (ID) of the fuel line and fittings

• Fuel line length, routing, bends or kinks, and securing clamps

• Extra fuel filters

• Fuel manifolds

• Antisiphon valves, shut‑off valves, and tank selector valves

• The number of 90‑degree fittings used

6. Engine coolant temperature.

7. How quickly the engine is shut off after operating at cruising or higher RPMs and how long the engine and engine

compartment are allowed to cool off after use.

8. The outside air temperature on the day the boat is being operated.

Eliminating Other Causes of Driveability Issues

NOTE: Before assuming the customer’s problem stems from vapor locking, make sure something else is not causing the

problem with operation.

Test for an air leak in the engine or boat fuel system. Check the tightness of all fuel fittings and clamps. Check for a cracked

housing where a brass fuel fitting is threaded in it.

IMPORTANT: Do not pressurize the boat’s fuel tanks in this test.

90-8M0149179 eng NOVEMBER 2018 © 2019 Mercury Marine Page 1B-7