Page 231 - Basic Principles of Textile Coloration

P. 231

220 DYEING MACHINERY

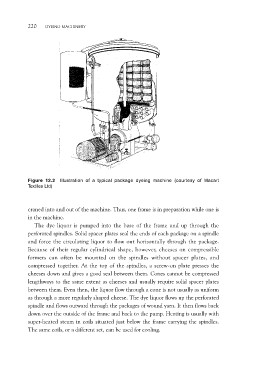

Figure 12.2 Illustration of a typical package dyeing machine (courtesy of Macart

Textiles Ltd)

craned into and out of the machine. Thus, one frame is in preparation while one is

in the machine.

The dye liquor is pumped into the base of the frame and up through the

perforated spindles. Solid spacer plates seal the ends of each package on a spindle

and force the circulating liquor to flow out horizontally through the package.

Because of their regular cylindrical shape, however, cheeses on compressible

formers can often be mounted on the spindles without spacer plates, and

compressed together. At the top of the spindles, a screw-on plate presses the

cheeses down and gives a good seal between them. Cones cannot be compressed

lengthways to the same extent as cheeses and usually require solid spacer plates

between them. Even then, the liquor flow through a cone is not usually as uniform

as through a more regularly shaped cheese. The dye liquor flows up the perforated

spindle and flows outward through the packages of wound yarn. It then flows back

down over the outside of the frame and back to the pump. Heating is usually with

super-heated steam in coils situated just below the frame carrying the spindles.

The same coils, or a different set, can be used for cooling.