Page 228 - Basic Principles of Textile Coloration

P. 228

DYEING MACHINES FOR LOOSE FIBRE AND SLIVER 217

K

C

I

HA

E

B

L

G

D

F

J

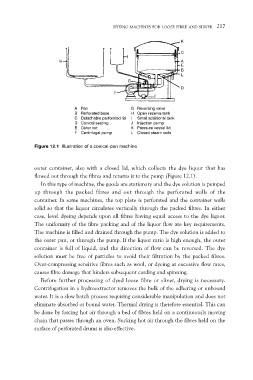

A Pan G Reversing valve

B Perforated base H Open reserve tank

C Detachable perforated lid I Small additional tank

D Conical seating J Injection pump

E Outer vat K Pressure vessel lid

F Centrifugal pump L Closed steam coils

Figure 12.1 Illustration of a conical-pan machine

outer container, also with a closed lid, which collects the dye liquor that has

flowed out through the fibres and returns it to the pump (Figure 12.1).

In this type of machine, the goods are stationary and the dye solution is pumped

up through the packed fibres and out through the perforated walls of the

container. In some machines, the top plate is perforated and the container walls

solid so that the liquor circulates vertically through the packed fibres. In either

case, level dyeing depends upon all fibres having equal access to the dye liquor.

The uniformity of the fibre packing and of the liquor flow are key requirements.

The machine is filled and drained through the pump. The dye solution is added to

the outer pan, or through the pump. If the liquor ratio is high enough, the outer

container is full of liquid, and the direction of flow can be reversed. The dye

solution must be free of particles to avoid their filtration by the packed fibres.

Over-compressing sensitive fibres such as wool, or dyeing at excessive flow rates,

causes fibre damage that hinders subsequent carding and spinning.

Before further processing of dyed loose fibre or sliver, drying is necessary.

Centrifugation in a hydroextractor removes the bulk of the adhering or unbound

water. It is a slow batch process requiring considerable manipulation and does not

eliminate absorbed or bound water. Thermal drying is therefore essential. This can

be done by forcing hot air through a bed of fibres held on a continuously moving

chain that passes through an oven. Sucking hot air through the fibres held on the

surface of perforated drums is also effective.