Page 234 - Basic Principles of Textile Coloration

P. 234

MACHINES FOR DYEING FABRIC 223

use of radio frequency dryers has become popular. As much water as possible is

removed by centrifuging and the packages then go into the RF dryer. The

oscillating electromagnetic field causes oscillation of the polar water molecules in

the package at the field frequency. This generates much heat. The degree of

heating depends on the amount of water at a given point in the package so that

drying is more uniform than in hot air. The power of the RF field is sufficiently

high that drying only takes a few hours.

12.4 MACHINES FOR DYEING FABRIC

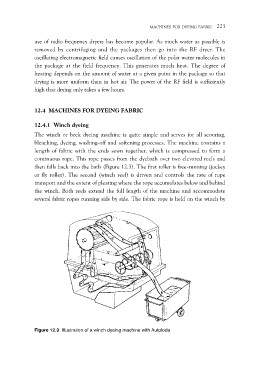

12.4.1 Winch dyeing

The winch or beck dyeing machine is quite simple and serves for all scouring,

bleaching, dyeing, washing-off and softening processes. The machine contains a

length of fabric with the ends sewn together, which is compressed to form a

continuous rope. This rope passes from the dyebath over two elevated reels and

then falls back into the bath (Figure 12.3). The first roller is free-running (jockey

or fly roller). The second (winch reel) is driven and controls the rate of rope

transport and the extent of pleating where the rope accumulates below and behind

the winch. Both reels extend the full length of the machine and accommodate

several fabric ropes running side by side. The fabric rope is held on the winch by

Figure 12.3 Illustration of a winch dyeing machine with Autoloda